Matching Casings - Advice Please

Posted: Sat Jun 18, 2011 9:37 am

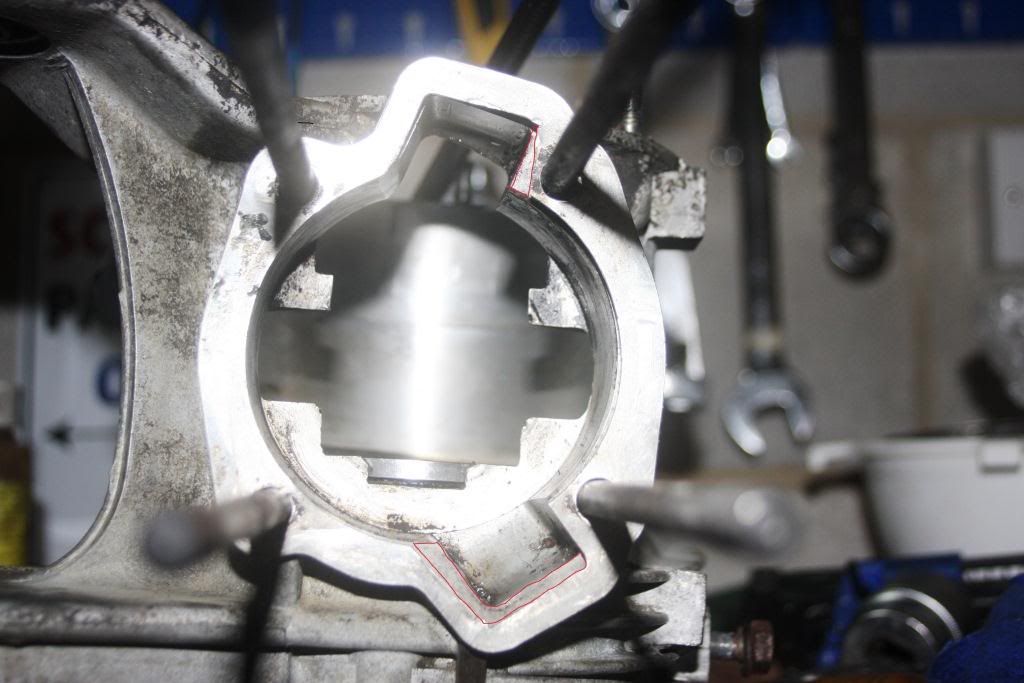

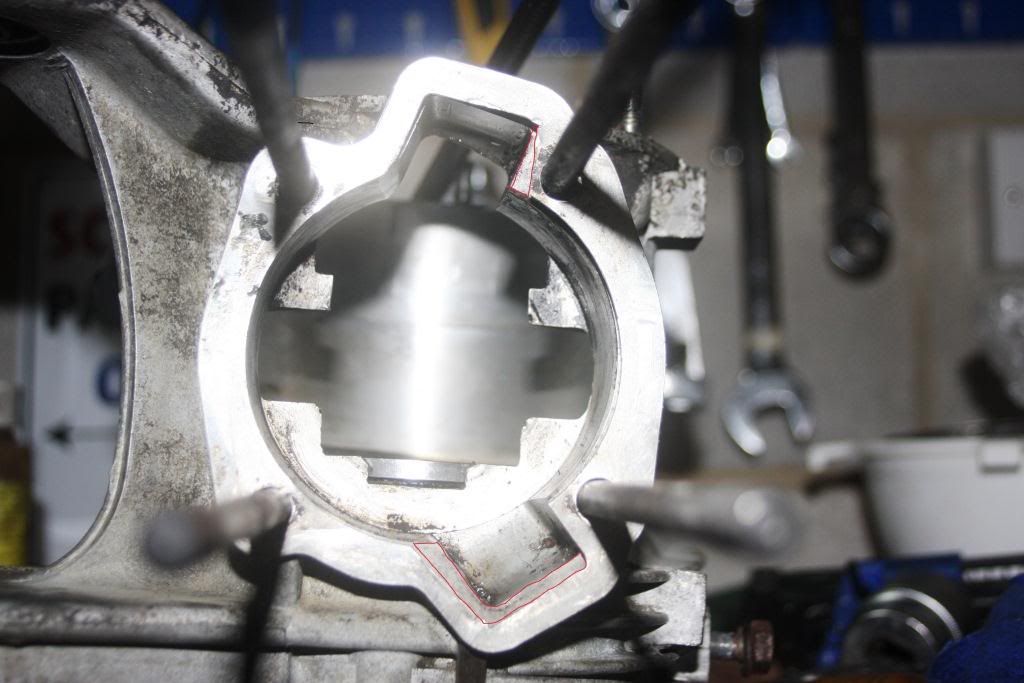

Late last year I slipped on a Rapido classic 200 barrel, whilst the engine was still in the frame of my Jet200. Time permitting, and I don’t have much, I am currently, renovating this Jet, including replacing the oil seals and checking rest of the motor. However, with the engine out, I have now matched the bottom gasket with the Rapido barrel and found that the casing transfers need to be enlarged, see photo. But can anyone help with the following:

• The transfer at the top of the picture (mag side). If I cut this back to the red line, there is only around 2mm to the stud. Clearly I can’t go that far without someone putting extra weld on, so what is a safe thickness to leave between the stud/casing.

• Looking through some of the threads, it looks like a dremel is out of the question. But could anyone give me a link to buy the right size and type of cutting tools for my drill or dremel.

• Will matching the transfers make a great difference? I know the answer is yes, but would like a bit of education/knowledge about the difference.

Many Thanks

Paul

• The transfer at the top of the picture (mag side). If I cut this back to the red line, there is only around 2mm to the stud. Clearly I can’t go that far without someone putting extra weld on, so what is a safe thickness to leave between the stud/casing.

• Looking through some of the threads, it looks like a dremel is out of the question. But could anyone give me a link to buy the right size and type of cutting tools for my drill or dremel.

• Will matching the transfers make a great difference? I know the answer is yes, but would like a bit of education/knowledge about the difference.

Many Thanks

Paul