Page 1 of 2

fork help

Posted: Tue Mar 29, 2011 5:08 pm

by sydduckett

have a set of series 3 li forks and am only able to get one link in. The other link wont go in as the side where the hole is has been bashed in, this happened when the links were taken out im guessing. Have taken to welders to see if he could do anything but no go....

Problem is that the side where the outside hole is has been pushed in by about 5 -10mm and needs to be pushed/pulled back out. Ideally a mini jack about 2 inches wide would be ideal but iv havent seen one of those for a while....or ever...

Any suggestions

Ta

Sef

Re: fork help

Posted: Tue Mar 29, 2011 5:16 pm

by shocky

ive done some like that i used a thick plate on the outside with a 12mm hole in it then on the inside i made another thick plate that suited the inside of the fork leg also with a hole i heated the forks till cherry red then bolted both together and tightened the nut and bolt till it pulled the bent bit out . i did remove the washer on the outside of the forks as it was bent anyway

Re: fork help

Posted: Tue Mar 29, 2011 5:27 pm

by paulmgreen

What Shocky said - best solution!

Re: fork help

Posted: Tue Mar 29, 2011 5:41 pm

by sydduckett

Did you leave the plates & nuts loosley in place prior to heating and then tighten up? Im presumming it would be way to hot to f**k about trying to do it after.....

Also sorry for being thick but did you have the nut on the outside when tightning down..?

As in, from the outside

threaded bolt

Large plate with 12m hole

nut

From the inside

thread through smaller plate with nut on

ta

ta

Re: fork help

Posted: Tue Mar 29, 2011 6:19 pm

by RICSPEED

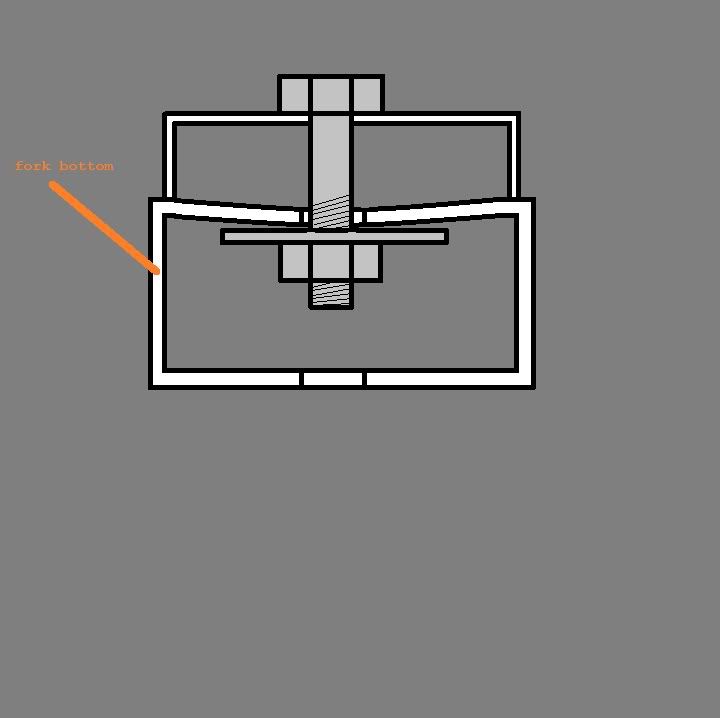

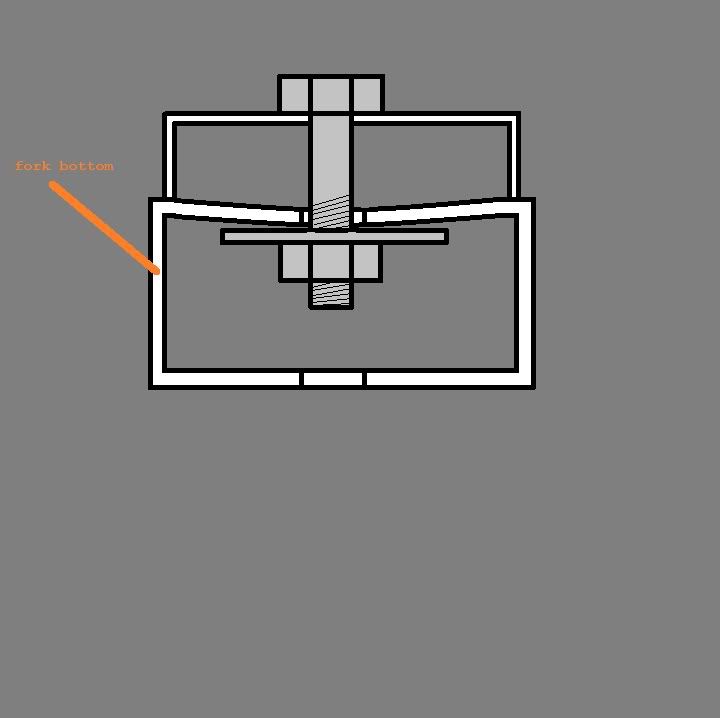

a drawing is in order

Re: fork help

Posted: Tue Mar 29, 2011 6:34 pm

by RICSPEED

Re: fork help

Posted: Tue Mar 29, 2011 10:31 pm

by shocky

sydduckett wrote:Did you leave the plates & nuts loosley in place prior to heating and then tighten up? Im presumming it would be way to hot to f**k about trying to do it after.....

Also sorry for being thick but did you have the nut on the outside when tightning down..?

As in, from the outside

threaded bolt

Large plate with 12m hole

nut

From the inside

thread through smaller plate with nut on

ta

ta

no i heated forks in a vice and sloted everything on after, im a welder by trade so welding gloves were worn . the nut was on the inside as rics drawing

Re: fork help

Posted: Tue Mar 29, 2011 11:26 pm

by paulmgreen

Ace drawing Ric!!! Star!

Re: fork help

Posted: Tue Mar 29, 2011 11:27 pm

by sydduckett

RICSPEED wrote:

This is action beyond the call, would be mentioned in dispatches for this back in the day....

ta

Re: fork help

Posted: Tue Mar 29, 2011 11:36 pm

by RICSPEED

not bad for 15 mins