Page 7 of 20

Re: lambretta 290 rotax

Posted: Tue Jan 03, 2017 1:52 pm

by st0kky

Hi Rich_T

Martin here, I'm the one that pointed Holty to Martin at Chiselspeed for the wider crank.

I've been running one of these wider cranks in an RB for a few years now. with a 64ml stroke

No problems.

You question about drive side, is..................

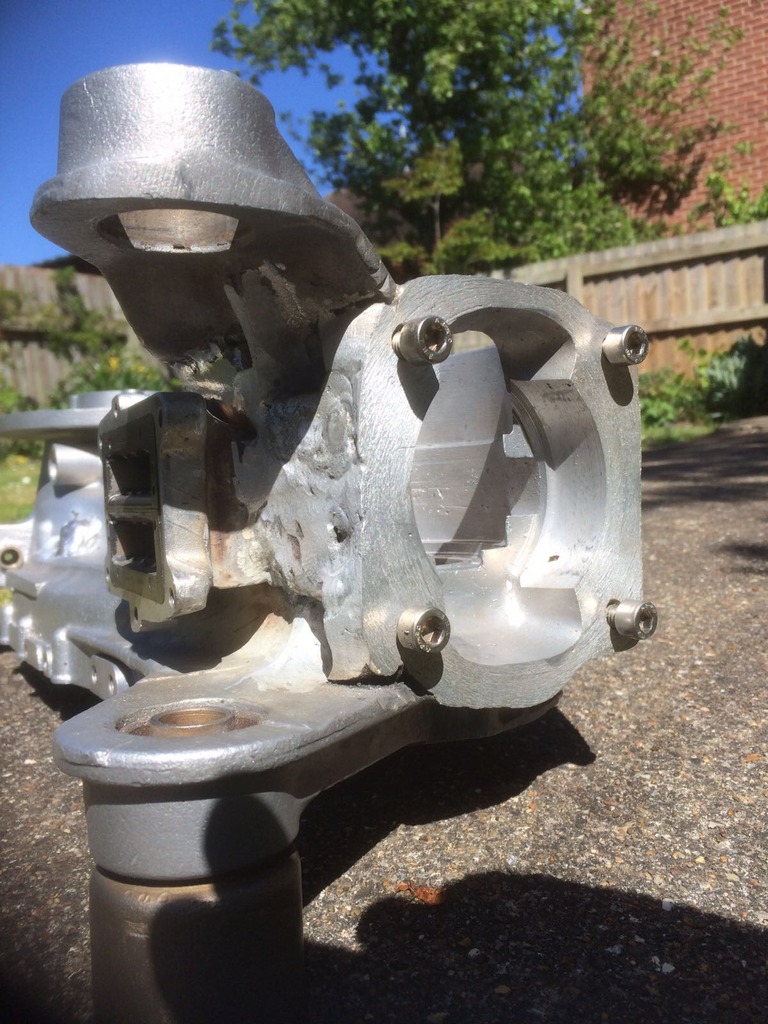

Use a Vespa clutch bearing on drive side (narrower than normal Lambretta one), with no bearing retaining plate, a small bit of meat needs taking out and hey presto it fits, with no changes to sprockets or clutch etc. On Holty's photo, the circlip is used to hold bearing in place, just needs a small groove cutting.

I did at the time worry about the oils seal going on a high power motor, but 3k - 4k later still no issues.

I did pop up some photos a few years ago on LCGB, if I can find them will bob on here

Re: lambretta 290 rotax

Posted: Tue Jan 03, 2017 8:04 pm

by holty

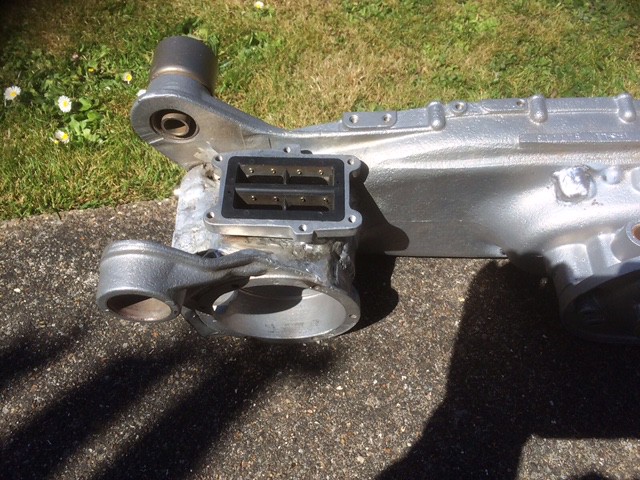

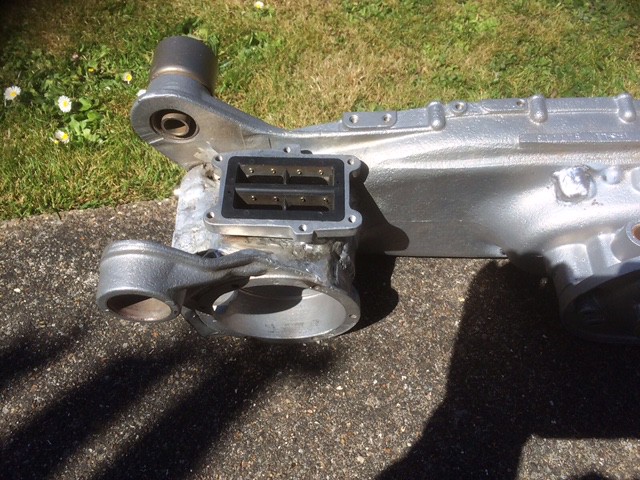

hi martin, thanks for the advice, ive got one of your pics here you can see the old bearing in place so the circlip groove was cut in the correct place

Re: lambretta 290 rotax

Posted: Tue Jan 03, 2017 8:04 pm

by holty

.

. by

stephen holt, on Flickr

Re: lambretta 290 rotax

Posted: Tue Jan 03, 2017 8:19 pm

by Rich_T

Very clever plan guys, good lateral thinking.

Re: lambretta 290 rotax

Posted: Wed Jan 04, 2017 12:00 pm

by st0kky

In my instance the credit goes to Martin at Chiselspeed.

Mines now been on the road and in use for about 2 1/2 years without issue.

Although does vibrate a tad !!

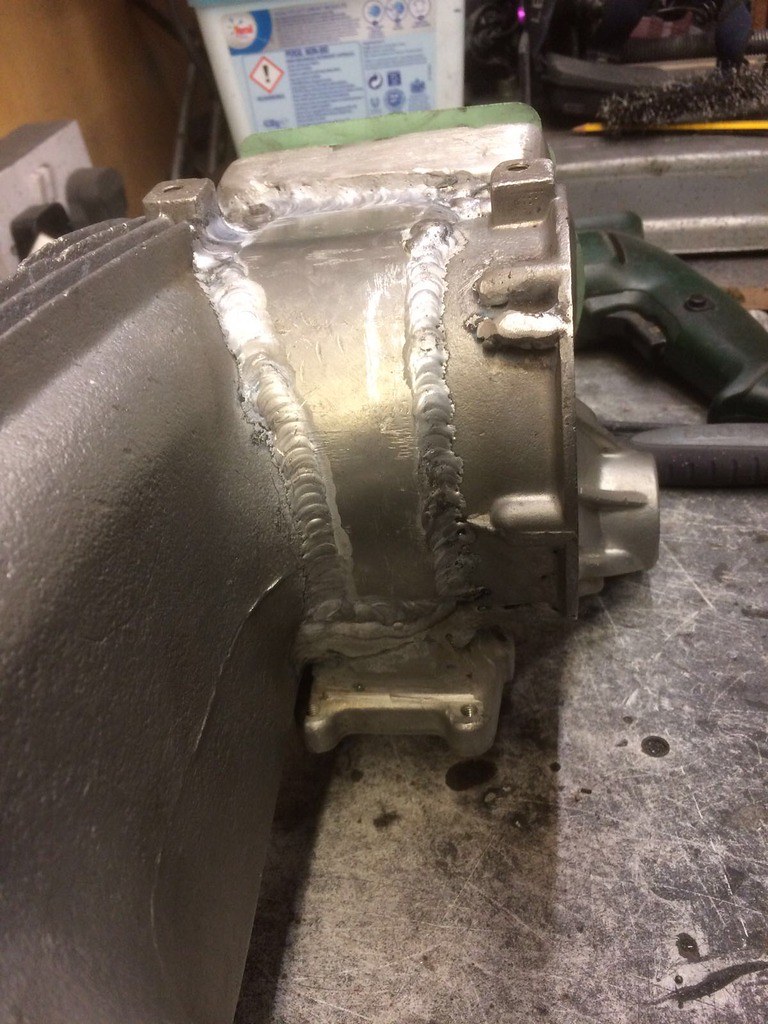

In the photo above, all bolts etc, are just to protect threads before blasting, although the ones normally used to hold bearing plate are in fact unused

Re: lambretta 290 rotax

Posted: Wed Jan 04, 2017 9:08 pm

by Rich_T

The vibration does not surprise me. I ran the numbers for the plus webs (101mm diam) with the standard piston and the balance was about 38% along the bore. Meaning the engine is likely to shake more front to back rather than up and down when you hit the engine mount specific frequency. If you get the opportunity to lighten the piston I would, well I certainly am for the more traditional cranks at least.

Re: lambretta 290 rotax

Posted: Sat Jan 07, 2017 4:50 am

by RManson

Unfortunately, no dyno results as of yet. Soon I hope, just gotta find one that can deal with something like this (IE, it's not a sport bike or a Harley). Also haven't had a chance to perfect the jetting yet so it's a bit moot as I don't know anyone that could handle both the tune and dyno session on something like this.

Seems like the Aprilia charging system is up to the requirements but I haven't had more than a full day's worth of riding to test things out and even then the battery was on its way out due to a faulty regulator/rectifier, so still have yet to fully vet the system. I don't see why it wouldn't be up to the challenge however.

Interesting about the vibration topic as I rode a friend's TS1 recently and my Rotax bike seemed much smoother. I chalked it up to the longer rod smoothing things out but who knows. As mentioned, with the larger, heavier piston, crank and rod, balancing the entire assembly is paramount to a finely tuned machined.

As to performance, I can say that when it was opened up at the SF Classic, nothing came around it! Very fun indeed.

Re: lambretta 290 rotax

Posted: Mon Jan 30, 2017 10:57 pm

by holty

im still waiting for my engine case to come back from welding, he told me it will be this week so fingers crossed, decided i would get the flywheel in my lathe and turn it down a bit, ended up weighing in at 1.6 kg

[img

IMG_0373_zpsioihw8xe

IMG_0373_zpsioihw8xe by

stephen holt, on Flickr][/img]

Re: lambretta 290 rotax

Posted: Fri May 05, 2017 9:53 pm

by holty

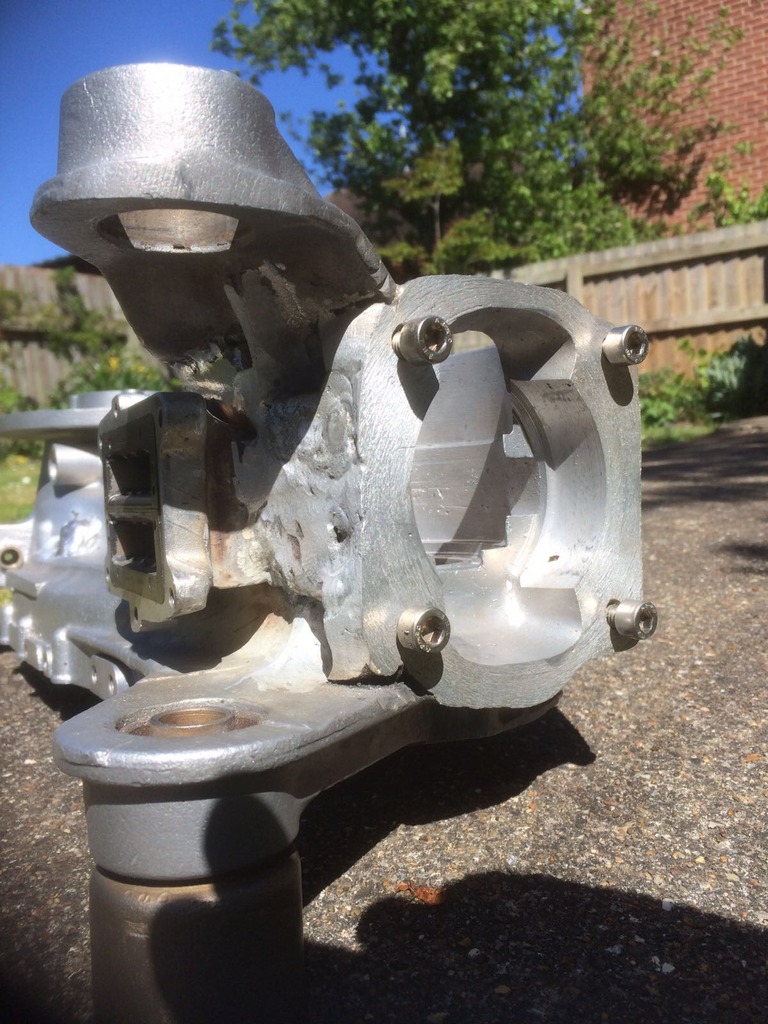

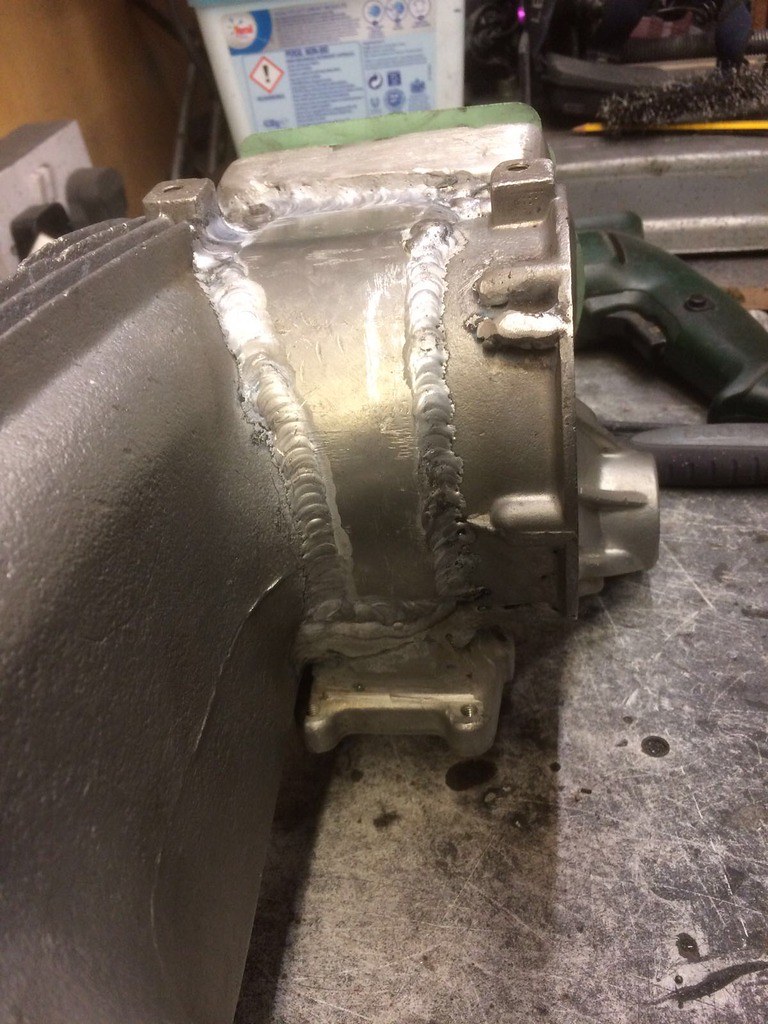

collected my case from tony at ajs today, he has done a good job, he said it was a pain to do, anyway all the welding is done and all i need to do is machine it , heres a couple of pics, ive started cutting the boost port, and ive done a tidy up job on the gearbox stud supports that were welded.

IMG_0617_zps1ucdloih

IMG_0617_zps1ucdloih by

stephen holt, on Flickr

IMG_0618_zpsxsv20sjk

IMG_0618_zpsxsv20sjk by

stephen holt, on Flickr

IMG_0619_zpsnvkjaedq

IMG_0619_zpsnvkjaedq by

stephen holt, on Flickr

Re: RE: Re: lambretta 290 rotax

Posted: Fri May 05, 2017 10:23 pm

by dazblakey

holty wrote:ive got hold of a scrap rb cylinder and cut off the part that houses the reedvalve, more cutting and shaping needed yet, heres roughly where its going

Please could you explain what a reed valve does please

Sent from my D6603 using Tapatalk