Well i stalled a bit over Christmas, but had a few hours on it this week

First problem was the seat , i havent seen a decent looking alternative seat on a LD. I toyed with altering an old Snetterton i had , but the most comortable position for me, is directly over the filler cap , and with a Snetterton what would of been a little uncomfortable

I love the look of the LD front seat with the two springs at the rear, the position is too far forward for me, but the position is again over the filler cap and would be impossible to access the cap

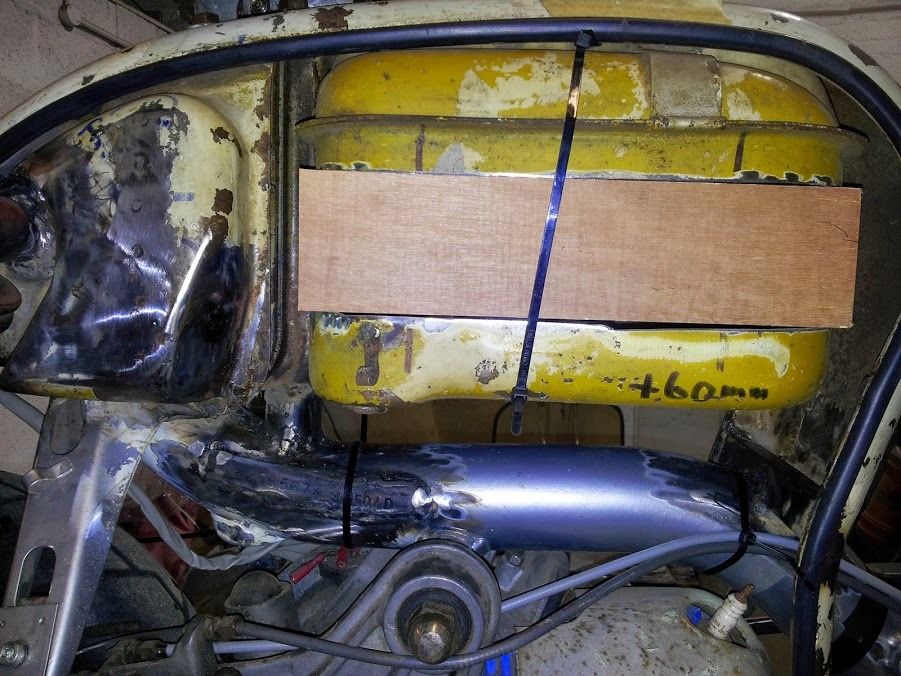

so i came up with an idea to make the seat tilt. I tried it first with a wooden template, then went on to a carboard template to transfer to some sheet steel and fabricated a bracket .

It only needs to tilt by about 25 degrees to gain access to the tank, ive still to make a catch for it and a way to adjust it back and forth a little whilst riding

Another job was the fork stem, this is too short by around 12mm to reach the top of the leggies. So i found a bit of scaffold tube, turned down the id a little to get the chrome ring and race to fit , and tacked in place.

So this in turn, meant the forks were 12mm too short, but also the LD fork are threaded all the way up to the top unlike the s3 forks i had. If i used the S3 forks the LD handle bar clamp is a very sloppy fit as the diameter is reduced. So out with the grinder again and its cut and shut time. Luckily i had a piece of tube the same size and the id of the fork tube , and just needed a smidge off on the lathe for a snug fit

When i was young my Mom said "if you haven't got anything nice to say, say nothing at all " ..................... and people wonder why I'm quiet around them !