rog60 wrote:J1MS,

As an utter novice to all this, I took your advice and bought the box of 100 asstd rubberized bits for alloy......absolutely brilliant.

I want to try some transfer port tidy-ups so would any of the e-bay type £20 - £40 die grinders be any good as a starting point and a small set of carbide grinding bits from a similar source.

I think that, to start off with, a least expensive outlay would be more sensible way to start??

Opinions greatly appreciated.........#

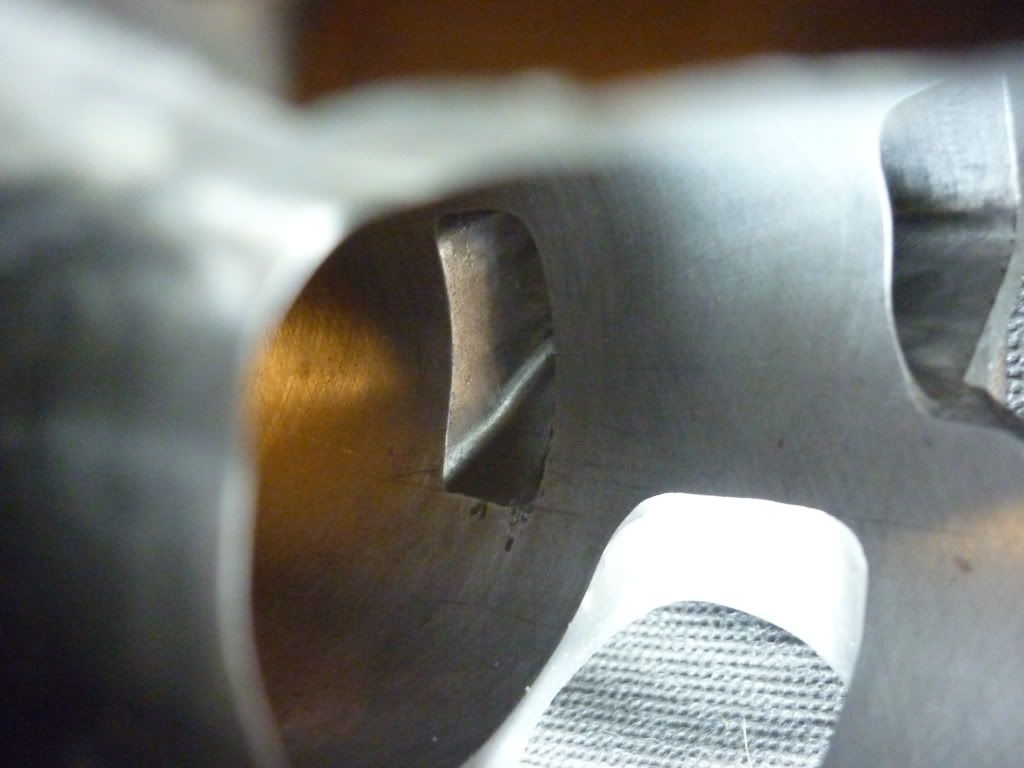

Great pics BTW.

I am no expert at porting, like most others I'm self taught. When you first try to port a barrel its more a case of finding out what doesnt work rather than what does.

The cheap options (some are very good for porting a Lambretta barrel) are the mini drills with a flexible shaft included in the kit.

B&Q did a mini drill 135 watts with a stand, tools included and a flex shaft for about £25 (I would highly recommend it) if they are in stock.

Machine mart also sell one its about £30 which hangs from a stand, but the B&Q one if you can get one is far more user friendly

http://www.machinemart.co.uk/shop/searc ... any/page/1... But there are many other makes offering similar packages.

Dremel make a couple of kits with a stand & flex shaft included but these are usually £50 plus, but are very good...(I seem to burn out Dremels unless I use them with the flex shaft) metal fillings seem to get into the motor too easily...

If you have a compressor then you can use an air powered pencil grinder, these are very small and light to use rev at speeds up to 75000 rpm and remove metal using a Tungsten burr very quickly, from around £25, I use one of these.

http://cgi.ebay.co.uk/RDGTOOLS-AIR-DIE- ... 286.c0.m14

The tools needed to give a decent finish to a port are not too expensive with (pointed tree barrel and flame shapes) 3mm shaft 6mm head tungsten's, some silicone carbide burrs and varying grades and sizes of mini flap wheels.

These used with a mini drill-flex drive or a air powered pencil grinder, then all of the barrel can be accessed except the transfers in the bore (although you can make some progress in the bore but not all of the port can be accessed)

cartrige roll kits in varying grades, that fit to an arbour are available for drill speeds up to 10000 rpm with a 6mm shaft pretty easy to use and polish up exhaust & inlet ports after cutting prior to finishing with finer grade mini flap wheels.

A very good place to get the cutting tools is ebay, or next weekend the Stafford show, as they have a lot of tool stalls inside that sell cutters and stuff for porting...

If trying to get a neat finish with Tungstens, then I use cross cut or double cut Tungstens, These are less prone to juddering & remove metal a little slower when used on a slower speed can give a reasonable finish without polishing... This type of Tungsten cloggs up very easily if used on aluminium...Like these

http://cgi.ebay.com/ebaymotors/Carbide- ... veQ5fTools available in 3mm shank......but these are 6mm shank but they can be used with a die grinder for fast metal removal on steel