[quote="Rich_T"]I'm affraid it is not possible to magically go to the machine shop and order up 40% squish band just like that. The vast majority of heads are all mild modifications of a standard Lambretta head because this is what is economicaly available to all.

-------------------------------

I have designed and made cylinder heads from scratch, I have also machined a number af cylinder heads. So I understand that the best is not always possible.

However to me that looks like a head that has had the absolute minimum removed.

Edited to tell how I machine a Lambretta head.

1 The head is mounted on a mandril at a slight angle so that the side of the head furthest from the plug is about 1mm proud.

2 I then skim the gasket face of the head till it is even.

3 Now I form the profile ( squish band ) machining until the squish is reasonably close to the plug thread.

4 I again skim the gasket face till the squish band has the required diameter (piston dia. pluss 1mm)

5 the combustion chamber is then given a light machining and can be finished by hand porting.

most machine shops will not machine a head this way. However, I have found that my method works.

GT Kit Jetting

It`s all powerfull white mans magic

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

- Rich_T

- Dealer

- Posts: 540

- Joined: Fri May 29, 2009 8:07 pm

- Main scooter: Li Special

- Location: Birmingham

- Contact:

You still won't get you 40% squish band and you'll end up with all the other problems too. Be my guest, try it and see.

I have several jig fixtures specifically designed for the purpose. With 150, 175 and 200 side squish heads you are very limited in your options, that is why the GT kit manuals point to modification of 125 centre squish as better candidates for reprofiling (material porosity allowing).

BTW, you really don't have to tell me how you machine a head.

I have several jig fixtures specifically designed for the purpose. With 150, 175 and 200 side squish heads you are very limited in your options, that is why the GT kit manuals point to modification of 125 centre squish as better candidates for reprofiling (material porosity allowing).

BTW, you really don't have to tell me how you machine a head.

Unless someone can correct me is this the first report I've seen of a GT kit going wrong? They always seemed bulletproof.

- soulsurfer

- registered user

- Posts: 2539

- Joined: Thu Jan 08, 2009 2:43 pm

- Location: The Garden Of England

- Contact:

Don't jump to conclusions. It's not the cylinder that seems to be the problem, it's the cylnder head, which I hope to check and report this week. Cylinder heads are supplied by whoever and are not part of the kit, mine was supplied by a dealer that supplied the cylinder and is not to be confused as a kit failure. The head is also not machined as stated in the GT manual.Matty wrote:Unless someone can correct me is this the first report I've seen of a GT kit going wrong? They always seemed bulletproof.

Watch this space ...

Turn On, Tune In, Cop out!

Rich_T wrote:

BTW, you really don't have to tell me how you machine a head.

temper temper,

the reason I said how I do cylinderheads, is incase any one else wanted to know a logical order and systematic aproach that may be usefull to them.

It`s all powerfull white mans magic

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

Not jumping to conclusions. I've watched your threads about his on this site and the LCGB site. I got the impression that it's had gone wrong, but looking back it appears that some sort of heat 'spike' is causing you all this anguish. If I was in your position I would fit the f@@king thing and stop bellyaching about the the EGT readings. Sorry to sound harsh but I've recently rebuilt an engine with a Ralph Saxelby tuned 225 Rapido kit. I fitted it as advised and will wait to see if it goes well. If it goes wrong, so be it and I'll deal with it there and then. It may be 100 miles or 20,000 miles. You see what I'm saying?soulsurfer wrote:Don't jump to conclusions. It's not the cylinder that seems to be the problem, it's the cylnder head, which I hope to check and report this week. Cylinder heads are supplied by whoever and are not part of the kit, mine was supplied by a dealer that supplied the cylinder and is not to be confused as a kit failure. The head is also not machined as stated in the GT manual.Matty wrote:Unless someone can correct me is this the first report I've seen of a GT kit going wrong? They always seemed bulletproof.

Watch this space ...

- soulsurfer

- registered user

- Posts: 2539

- Joined: Thu Jan 08, 2009 2:43 pm

- Location: The Garden Of England

- Contact:

No I don't, When you've ignored the EGT on a well respected tuner's advice and had an expensive repair to a TS1 as a result only last month and then see the same symptons on another engine that seems impossible to jet correctly then tell me to stop bellyaching. It's not working and therefore not useable as it is, is that okay with you?Matty wrote:it appears that some sort of heat 'spike' is causing you all this anguish. If I was in your position I would fit the f@@king thing and stop bellyaching about the the EGT readings. You see what I'm saying?soulsurfer wrote:Don't jump to conclusions. It's not the cylinder that seems to be the problem, it's the cylnder head, which I hope to check and report this week. Cylinder heads are supplied by whoever and are not part of the kit, mine was supplied by a dealer that supplied the cylinder and is not to be confused as a kit failure. The head is also not machined as stated in the GT manual.Matty wrote:Unless someone can correct me is this the first report I've seen of a GT kit going wrong? They always seemed bulletproof.

Watch this space ...

Turn On, Tune In, Cop out!

I think that there is no way that the head in question could be skimmed and reproiled to give a 40% Squish band, as most of the material required has since been removed...

However, if another head was used I think its possible (with the right choice of standard head) to obtain upto a 50/50 squish & combustion area... by doing a skim and reprofile, as a 190 head (65mm dimeter) I did a few years back had a combustion area under 50% and a squish band over 50% when checked...

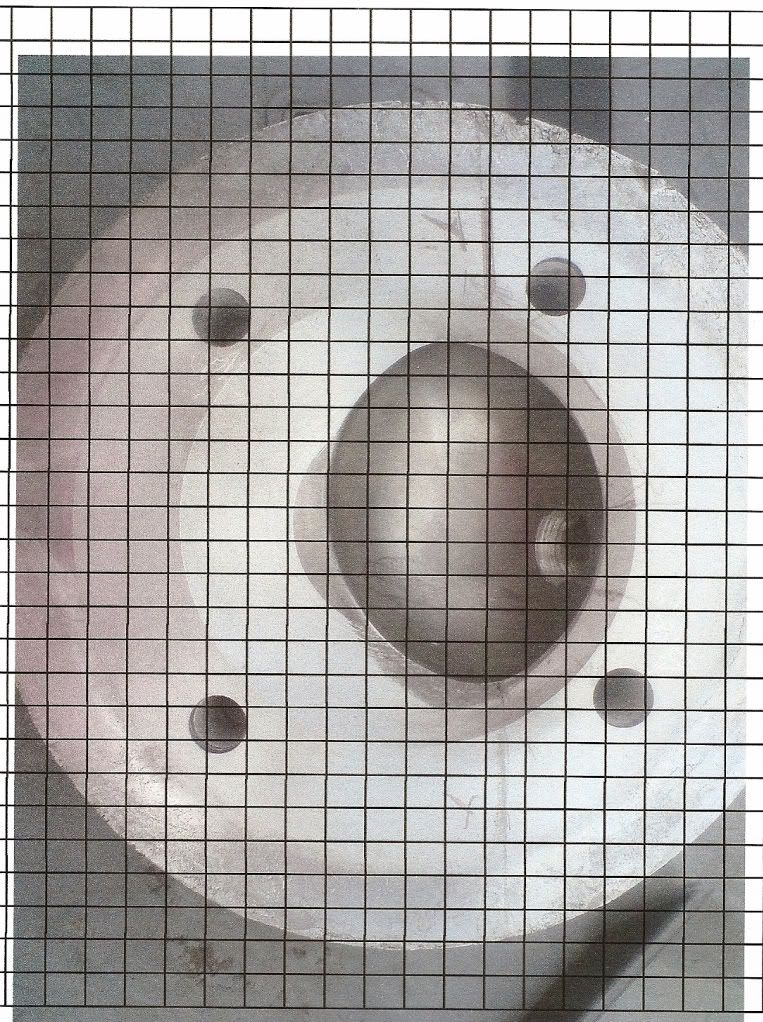

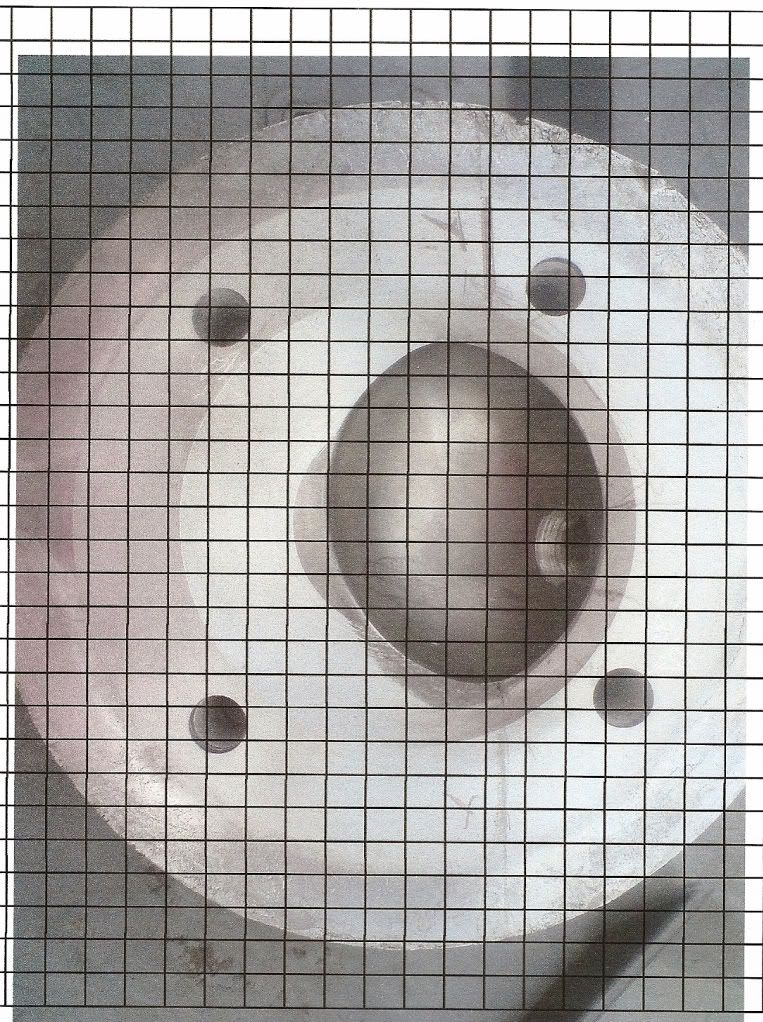

Easiest and quickest way to check is to print onto a transparent sheet and then overlay on the cylinderhead or even better if you have a printer & digi camera take a photo and print it over size on A4 then overlay the graph paper onto this... Then just count full squares over squish band and same over the combustion area.. A little old skool I know, but his will give an accurate enough calculation, and from this the percentages of each can be worked out...

I have just done a TS 225 head this way and its aproximately 55% Combustion 45% Squish... Thats by my calculations...

This is another head I was about to modify the combustion chamber on Its for a TS1 the newer AF head... I wanted to centralise the Combustion Chamber as the sit towards the mag sid a little I have marked in pencil to the right of the plug the metal to come off... But I have quickly overlayed a grid for now just to show how I work out Squish as a %

The Pencil lines with T next to them are where the transfers relate to the head itself lines drawn up from the barrel... will center the combustion chamber on this for a more even loop scavange & combustion...

However, if another head was used I think its possible (with the right choice of standard head) to obtain upto a 50/50 squish & combustion area... by doing a skim and reprofile, as a 190 head (65mm dimeter) I did a few years back had a combustion area under 50% and a squish band over 50% when checked...

Easiest and quickest way to check is to print onto a transparent sheet and then overlay on the cylinderhead or even better if you have a printer & digi camera take a photo and print it over size on A4 then overlay the graph paper onto this... Then just count full squares over squish band and same over the combustion area.. A little old skool I know, but his will give an accurate enough calculation, and from this the percentages of each can be worked out...

I have just done a TS 225 head this way and its aproximately 55% Combustion 45% Squish... Thats by my calculations...

This is another head I was about to modify the combustion chamber on Its for a TS1 the newer AF head... I wanted to centralise the Combustion Chamber as the sit towards the mag sid a little I have marked in pencil to the right of the plug the metal to come off... But I have quickly overlayed a grid for now just to show how I work out Squish as a %

The Pencil lines with T next to them are where the transfers relate to the head itself lines drawn up from the barrel... will center the combustion chamber on this for a more even loop scavange & combustion...

Last edited by J1MS on Sun Aug 02, 2009 8:51 pm, edited 2 times in total.

Cool with me. I'll do things my way, you do things with yours. I'll read with interest how it goes.soulsurfer wrote:No I don't, When you've ignored the EGT on a well respected tuner's advice and had an expensive repair to a TS1 as a result only last month and then see the same symptons on another engine that seems impossible to jet correctly then tell me to stop bellyaching. It's not working and therefore not useable as it is, is that okay with you?

Virtually every Lambretta I get on the dyno has a period in the fuel/air reading where it will go rich to start with and then weak and back down to richness. As has been stated on this forum before it often happens around 5500rpm but not always.

Bikes with expansion chambers do it more and there seems to be a pattern developing with bikes with either Vforce reeds or RB reed petal arrangements.

This is very difficult to carburate out and usually involves a compromise.

I don't want to say anything untill its proven but there may be a solution to this but suffice to say its not a new problem.

What I will say is that this problem has always been there on lots of different scooters and is a 2 stroke problem. The EGT is simply showing you something you weren't aware was there before.

What I tell everyone that comes on the dyno is that you should never hold a tuned Lambretta at a part throttle opening for any length of time but be constantly altering the throttle position unless its flat out which is often its safest position

My advice is that if it spikes but dissapears if you ride through it just know that its there and ride around it.

Bikes with expansion chambers do it more and there seems to be a pattern developing with bikes with either Vforce reeds or RB reed petal arrangements.

This is very difficult to carburate out and usually involves a compromise.

I don't want to say anything untill its proven but there may be a solution to this but suffice to say its not a new problem.

What I will say is that this problem has always been there on lots of different scooters and is a 2 stroke problem. The EGT is simply showing you something you weren't aware was there before.

What I tell everyone that comes on the dyno is that you should never hold a tuned Lambretta at a part throttle opening for any length of time but be constantly altering the throttle position unless its flat out which is often its safest position

My advice is that if it spikes but dissapears if you ride through it just know that its there and ride around it.