well....

powdercoat was erm, how do I put this politely and not offend the swear filter.... LOL

dont think they washed it or even blew it down after blasting as theres grit in the coating over most of the legshields

despite toe tagging and making it perfectly clear, one of the parts is the wrong colour, ironically its the best coated part!!

the black parts, ie my swingarm and forks, looked ok, until I accidently splashed some thinners in the garage and some went on it, and the powder dissolved immediately and left holes through to the steel.

anyway, Im carrying on with it, just very dissapointed and now feel sad that instead of it being a scooter that maybe people would say, hey did you see that bike engined build in the car park, it will be the one with god awful paintjob

Tony at fibreglassthings has come to my partial rescue, the guys a legend, I was looking for a new pair of sidepanels, he had a pair from his own personal scooter and did me a good deal on them, over weekend he rang to tell me he went to pack them but they been damaged, I was about to cry and give it all up when he says no worry, I gelled the mould and laying up a new pair for you same price, very small world as I used to be a fibreglass laminator and pattern fabricator on a farm next to where he is now.

hes a great bloke and so nice to hear that Essex accent on the phone, I been away too long might have to go home for a bit.

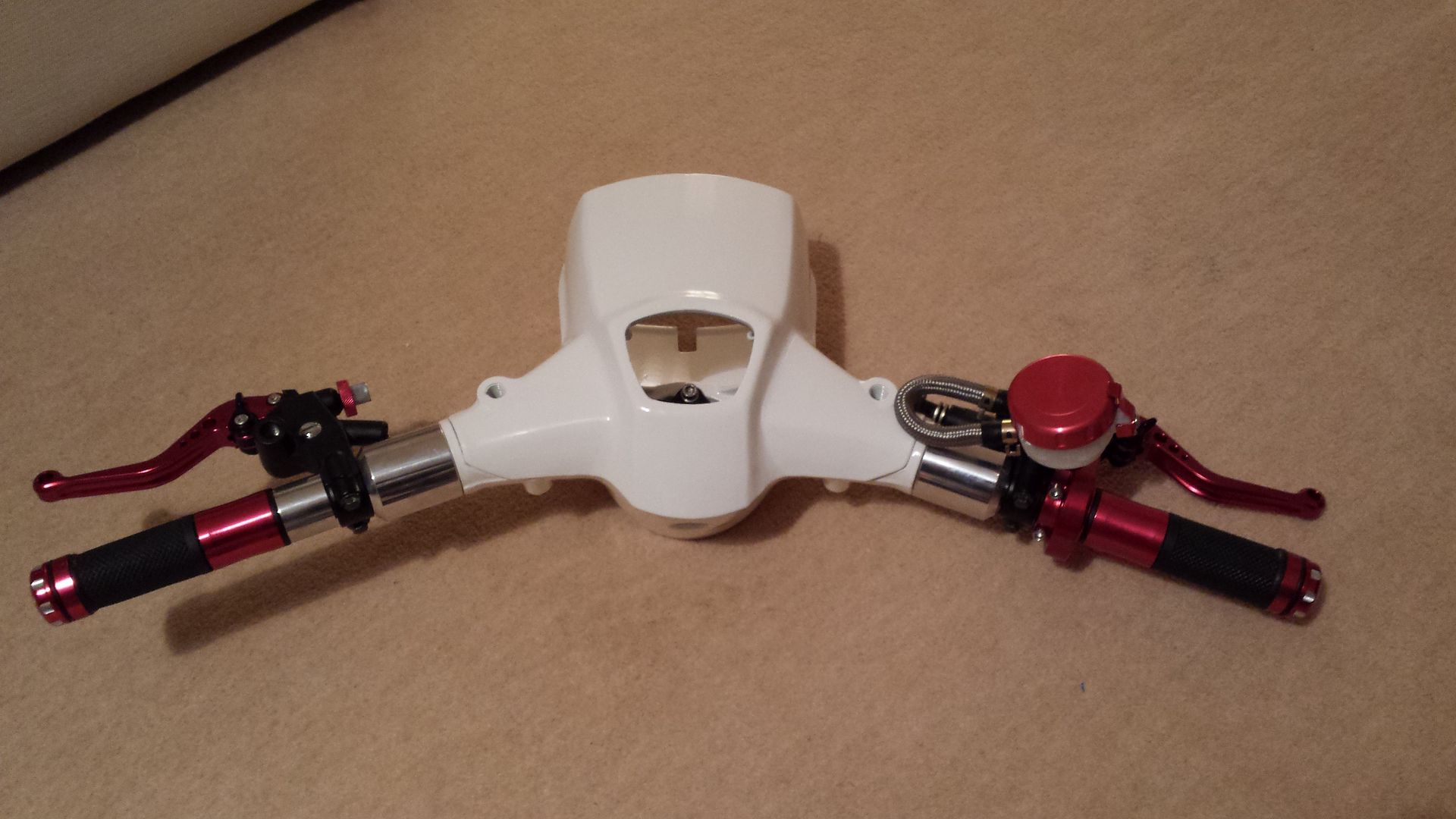

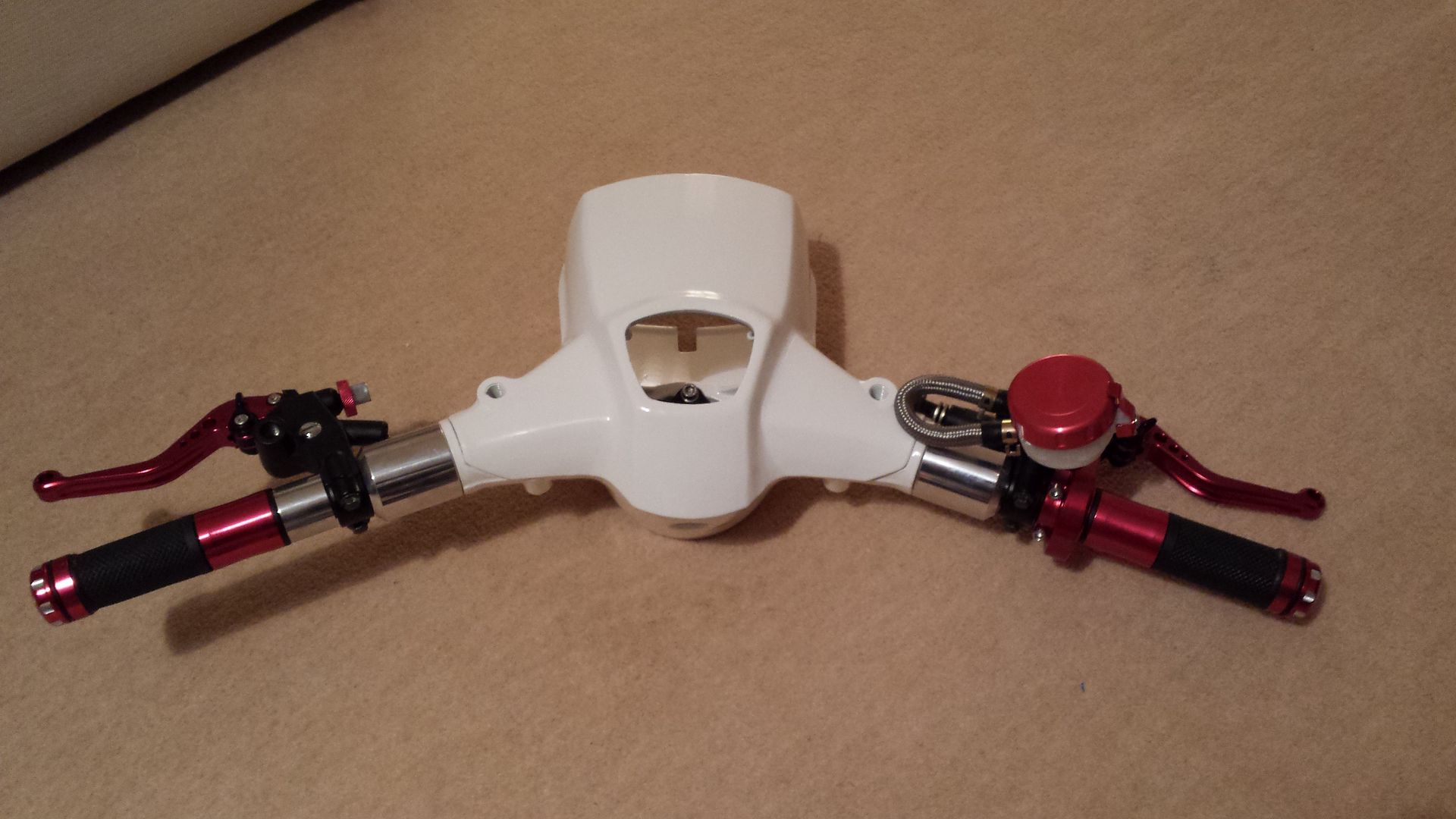

so I have been doing bits with it and heres a few pics of where its at now, the headset top will be getting sprayed red to break up the white.

rear grill, sandblasted, then sprayed with PJ1 exhaust paint, and baked

underseat view, spent time shimming the rubbers on the underside of the seat so that you have to push it down a bit to get the latch to click, that way its rock solid, no movement, and no rattling about if its sat running.

chain adjuster plate etc, I made the bits to go in the box section from round alloy bar, bored and reamed to suit 15mm axle, then drill and tapped into the side, fitted threaded rod to provide adjustment, 2 bits of alloy flat, cut to size on flat bed saw, then put a lip round it also on the saw LOL, so that they locate and sit into the box section

engine on its arm, loads still to go on it, but getting close to being bolted back into the frame, just want to try and get as much as possible done while its out and up on the bench, rather than scrabbling about the floor

rear engine bolt will be replaced, just waiting for more stock to make a new bolt from