thats good as im just in the process of definning a ts1 barrel for watercooling so would really be intrested if you need a guinea pig lol !Rich_T wrote:I saw a similar PV to this fitted to a cylinder MB did. Not sure if it was from a larger form of cylinder like Bombardier or SeaDoo. There are several problems, firstly the close proximity of the plastic parts to the exhaust and secondly the valve removes alot of fin cooling area in the place it is most needed (directly above the exhaust). This is why it is done on a water cooled cylinder.

We are discussing the possibilities to supply the PV machined part as a piece for tuners to weld in by themselves or to build a moster group 6 engine. I suspect that the group 6 engine might come around once this Gilera project has finished and fuel injection is done.

Messing about with a Gilera Runner

is this the rave unit of the aprilia ?? .. same as rocho i have an rb getting l c'd at guys at the mo

Its in bits scooter club: www.facebook.com/groups/132415046859320

- Rich_T

- Dealer

- Posts: 540

- Joined: Fri May 29, 2009 8:07 pm

- Main scooter: Li Special

- Location: Birmingham

- Contact:

In principle it is the same unit that is used on RS125 and Rotax Max kart engines. There are some technical and commercial difficulties in using the Aprilia solenoid in this application. The Rotax Max is easier to modify and cheaper to impliment which was the driving factor.

From a technical stand point a solenoid operation with a suitable ECU would be better but it added nearly £400 to the bill of materials which is a bit of a killer. On the upside, once the functionality is proved in this option a solenoid solution can be retro-fitted if required.

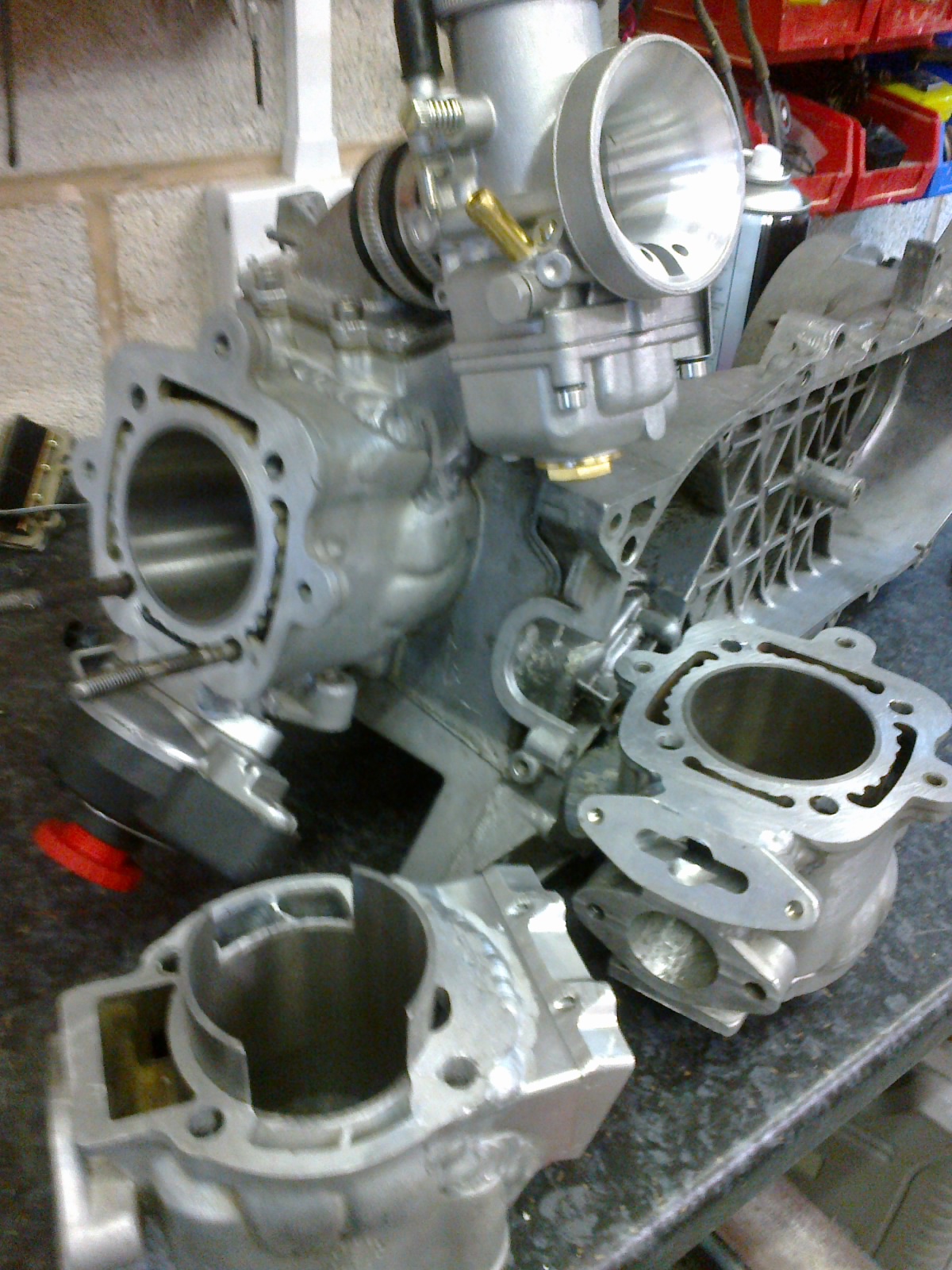

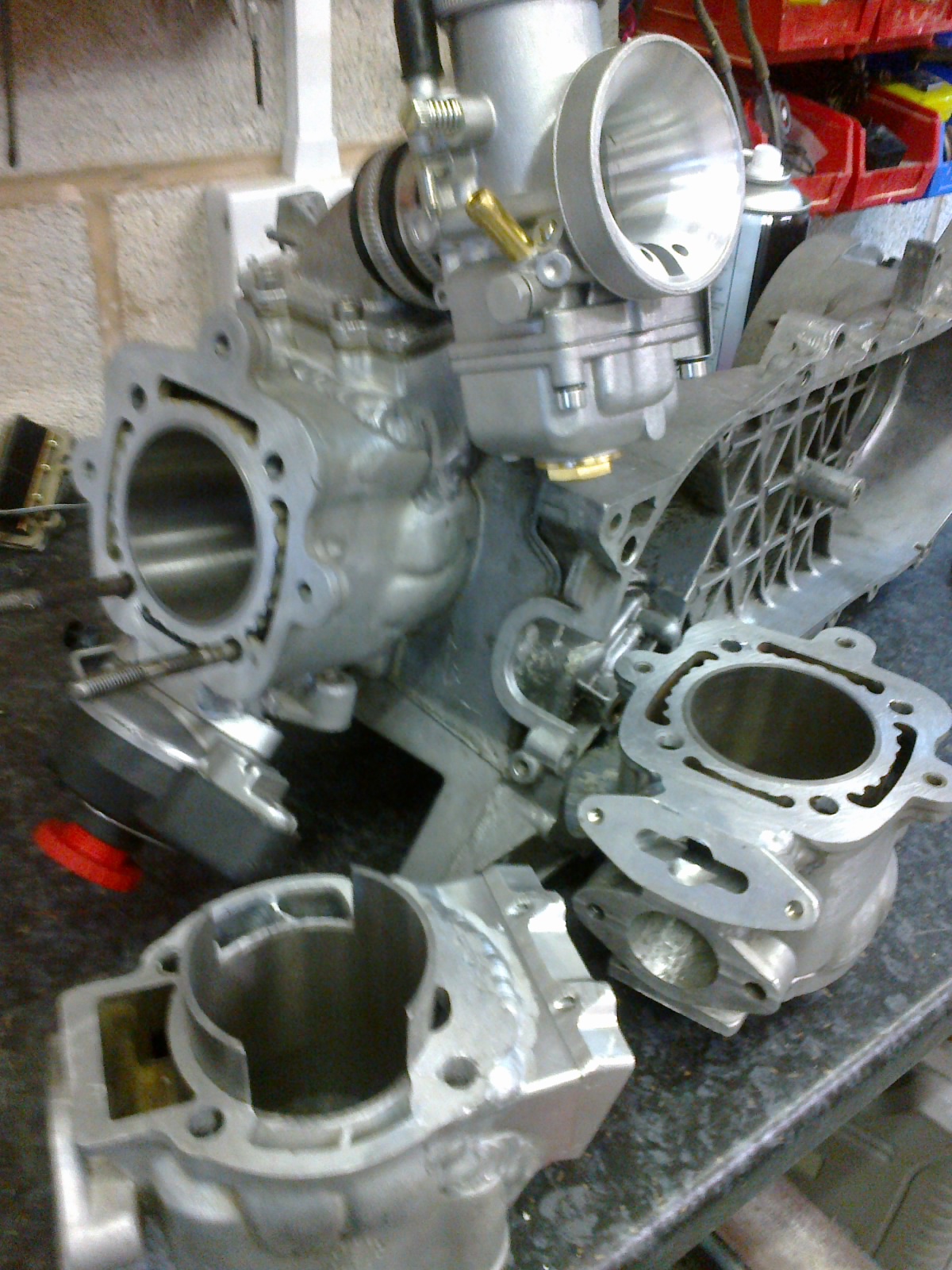

The second op welding, final bore and liner fit was done today. Next stop, re-drilling holes and a few other machining ops that require long reach tools, DRO and a bigger mill than Mr Topper's. So far, touch wood, it is going together very well and we've learnt a lot about doing these type of modifications and what is possible in future.

You'll see in the first pictures the barrel is held in a special jig fiture which is used to present the barrel at the correct angles for milling. To achieve this with Lambretta barrels will require the same type of fixture to be made. Consequently converting TS or RB barrels will require a fair bit of initial investment, far more than the cost of fitting the PV insert.

Additionally, the Rotax/RS PV gate may be too narrow for a 70mm bore so you may need to use a different type which will require sourcing and development. It all adds cost, so whatever your initial estimate for an LC barrel you can expect to add at least £300 to build in the PV assuming everything works out of the box with no glitches.

From a technical stand point a solenoid operation with a suitable ECU would be better but it added nearly £400 to the bill of materials which is a bit of a killer. On the upside, once the functionality is proved in this option a solenoid solution can be retro-fitted if required.

The second op welding, final bore and liner fit was done today. Next stop, re-drilling holes and a few other machining ops that require long reach tools, DRO and a bigger mill than Mr Topper's. So far, touch wood, it is going together very well and we've learnt a lot about doing these type of modifications and what is possible in future.

You'll see in the first pictures the barrel is held in a special jig fiture which is used to present the barrel at the correct angles for milling. To achieve this with Lambretta barrels will require the same type of fixture to be made. Consequently converting TS or RB barrels will require a fair bit of initial investment, far more than the cost of fitting the PV insert.

Additionally, the Rotax/RS PV gate may be too narrow for a 70mm bore so you may need to use a different type which will require sourcing and development. It all adds cost, so whatever your initial estimate for an LC barrel you can expect to add at least £300 to build in the PV assuming everything works out of the box with no glitches.

Any plans to do anything with a vespa gts engine 300/250

If you've got the tooling are you going to offer this as a service in future on these runner barrels .? .

- Rich_T

- Dealer

- Posts: 540

- Joined: Fri May 29, 2009 8:07 pm

- Main scooter: Li Special

- Location: Birmingham

- Contact:

Sorry, no plans to do anything with 4T engines. Years go I looked at making a supercharger for the leader engine but the engine main bearing shells were not up to it.

I'd have to think very carefully about doing anymore of these Runner barrels. The best solution would be to cast a new barrel.

I'd have to think very carefully about doing anymore of these Runner barrels. The best solution would be to cast a new barrel.

- Rich_T

- Dealer

- Posts: 540

- Joined: Fri May 29, 2009 8:07 pm

- Main scooter: Li Special

- Location: Birmingham

- Contact:

Latest progress, Liners in & cut to length, power valve slot cut through, transfers cut through skirt, cylinder studs cut through. Some more rough machining still to do before the matching and flowing work starts.

So far it has take twice as long as I expected not helped by the long reach milling cutters not being quite as long as I'd hoped.

Did the first offer up to the casings today and deciding which way is more economic (welding up the old reed valve or fabricating a cover and stuffer).

Pretty sure we'll miss the shoot out date as I've got the kids next week so I'm effectively grounded.

So far it has take twice as long as I expected not helped by the long reach milling cutters not being quite as long as I'd hoped.

Did the first offer up to the casings today and deciding which way is more economic (welding up the old reed valve or fabricating a cover and stuffer).

Pretty sure we'll miss the shoot out date as I've got the kids next week so I'm effectively grounded.

they do look sweet though

Its in bits scooter club: www.facebook.com/groups/132415046859320

i could do with one of these barrels right about now as im looking to upgrade my blew up 172  rich could you do anything to a 180/172 like a steel liner or ceramic big bore kit for me ?190 or 200cc would be nice

rich could you do anything to a 180/172 like a steel liner or ceramic big bore kit for me ?190 or 200cc would be nice

-

WINTERMODEL150

- registered user

- Posts: 436

- Joined: Sun Oct 17, 2010 5:31 pm

- Main scooter: lambretta ld auto

- Contact:

Daft question rich,but have you fitted this into a frame yet with modification carried out ?

Dean

Dean