It does concern me that there might be an underlying problem other than crap fuel that caused it to happen, as it looks like the barrell may need replating

As it is the family holiday is now cancelled

I stand corrected. I have to say i've yet to have a problem on 95ron with 2% octane booster added. Maybe time to up the compression and run Super!ktmh5 wrote:Wrong, Super Unleaded contains less, and in lots of cases, Zero Ethanol. Check this out :-richie wrote:Hi there, Super unleaded contains a higher percentage of ethanol, i'd stick to stock 95ron unleaded and add octane booster if you need to. I also use a quality oil that is compatable with alcohol fuels

http://www.groups.tr-register.co.uk/wes ... pdate.html

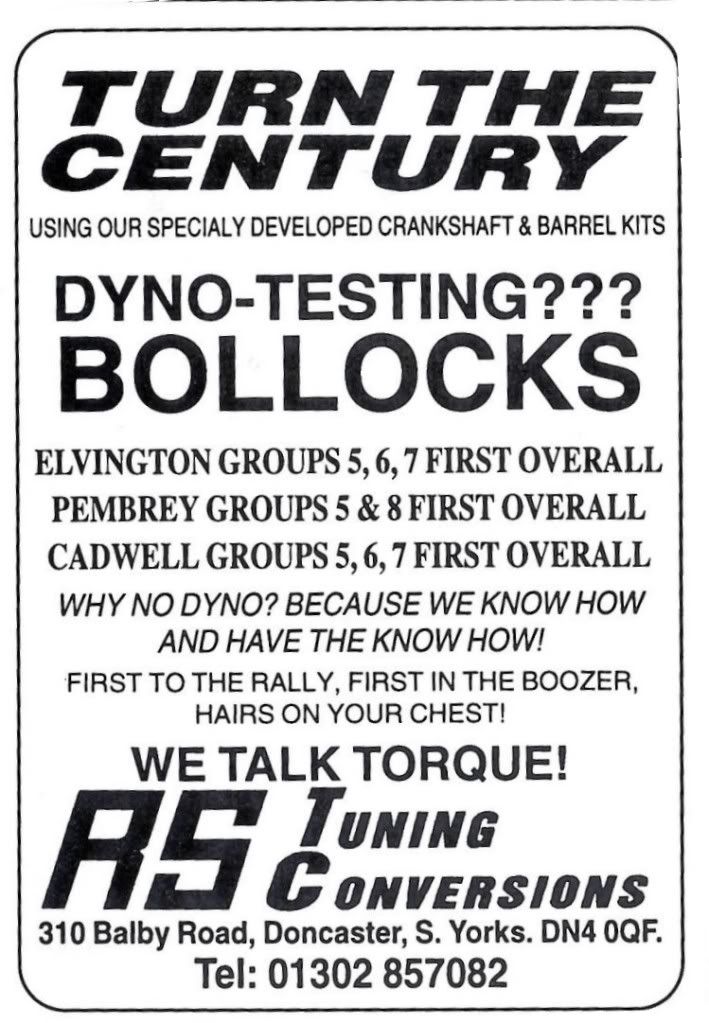

Rich, well said! Another current problem that I see time and time again, which I feel is totally linked to 'dyno tuners' is that today's improved ring quality is causing the tuner to feel too confident in the piston's ability to cope with wider exhaust ports. Yes, a dyno will always highlight the performace improvement that results from wider exhaust ports and increased areas, however, just because the rings will cope for perhaps a few thousand miles doesn't mean that it is the right thing to do. Many of the people that I've known to drop rings on expensive kits have had them ported by tuners that have a dyno in house and examination of the damage does suggest that the rings had been dropping into the exhaust port before they finally gave up and broke, taking the piston and bore with themRich_T wrote:The most common dynos around are inertia dynos. These will not replicate a fixed load on an engine at a fixed speed. The most common example of this would be accelerating to 60mph then backing off the throttle to cruise at 60mph. Once the throttle is backed off in this condition the AF ratio will be different from when the dyno would read AF ratio at that speed. Consequently there has to be a very good proportion of sensible judgement in selection of mid range jetting. The principle difference being road use and application not hard acceleration.

I am strongly of the opinion that a large majority of holed pistons on alloy kits are not soley down to dodgy fuel but a combimation of over confident compression ratios and over lean jetting for road use. Just because the piston gets holed in the last 6 miles does not signify that the root cause has been in the last 6 miles. More like the preverbial straw has only been recent, be that fuel or a combination of weather conditions.

Reliance on inertia dyno to deliver you good data to build a reliable road engine is pretty risky, there is a tendancy to chase settings for the chest beating BHP reading and this leads to leaner jetting and higher compression. If this route is followed then it's only a matter of time before disaster strikes.

There is a certain amount of denial about alloy barrel reliability. 10 years or so ago, it was a common cry that plated alloy barrels are fantastic because they don't sieze like iron barrels. For sure, an alloy barrel is far more forgiving with jetting and on the dyno this is commonly over looked in the persuit of BHP readings. The peril in this approach is that it stokes up expensive problems for the future. Unlike an iron kit, the alloy barrel will not warn you with a light seize, it just holes the piston and possibly a lot worse.

If you want to reliably get to your destination then it is common sense to built a road going engine to take into account variations in pump fuel and this means not pushing compression and jetting to the limit. You have to remember these engines are late 50's, they lack all of the sophistication of a modern two stroke so you have to listen to them carefully.

Now im sure ive heard this before somewhere.................................................................................................................................................Adam_Winstone wrote:Rich, well said! Another current problem that I see time and time again, which I feel is totally linked to 'dyno tuners' is that today's improved ring quality is causing the tuner to feel too confident in the piston's ability to cope with wider exhaust ports. Yes, a dyno will always highlight the performace improvement that results from wider exhaust ports and increased areas, however, just because the rings will cope for perhaps a few thousand miles doesn't mean that it is the right thing to do. Many of the people that I've known to drop rings on expensive kits have had them ported by tuners that have a dyno in house and examination of the damage does suggest that the rings had been dropping into the exhaust port before they finally gave up and broke, taking the piston and bore with themRich_T wrote:The most common dynos around are inertia dynos. These will not replicate a fixed load on an engine at a fixed speed. The most common example of this would be accelerating to 60mph then backing off the throttle to cruise at 60mph. Once the throttle is backed off in this condition the AF ratio will be different from when the dyno would read AF ratio at that speed. Consequently there has to be a very good proportion of sensible judgement in selection of mid range jetting. The principle difference being road use and application not hard acceleration.

I am strongly of the opinion that a large majority of holed pistons on alloy kits are not soley down to dodgy fuel but a combimation of over confident compression ratios and over lean jetting for road use. Just because the piston gets holed in the last 6 miles does not signify that the root cause has been in the last 6 miles. More like the preverbial straw has only been recent, be that fuel or a combination of weather conditions.

Reliance on inertia dyno to deliver you good data to build a reliable road engine is pretty risky, there is a tendancy to chase settings for the chest beating BHP reading and this leads to leaner jetting and higher compression. If this route is followed then it's only a matter of time before disaster strikes.

There is a certain amount of denial about alloy barrel reliability. 10 years or so ago, it was a common cry that plated alloy barrels are fantastic because they don't sieze like iron barrels. For sure, an alloy barrel is far more forgiving with jetting and on the dyno this is commonly over looked in the persuit of BHP readings. The peril in this approach is that it stokes up expensive problems for the future. Unlike an iron kit, the alloy barrel will not warn you with a light seize, it just holes the piston and possibly a lot worse.

If you want to reliably get to your destination then it is common sense to built a road going engine to take into account variations in pump fuel and this means not pushing compression and jetting to the limit. You have to remember these engines are late 50's, they lack all of the sophistication of a modern two stroke so you have to listen to them carefully.

I think that there needs to be more consideration of performance vs long-term reliability.

Adam