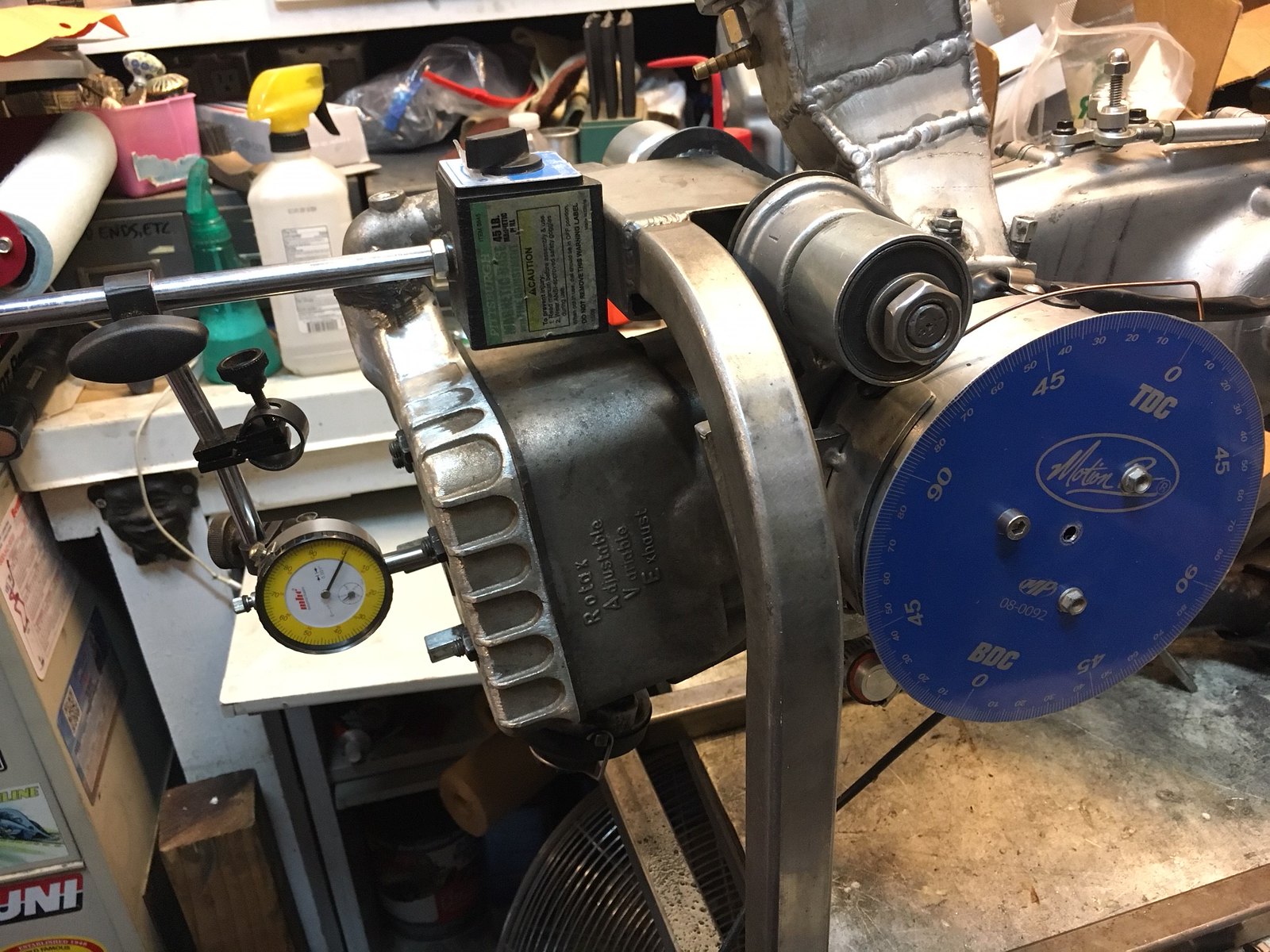

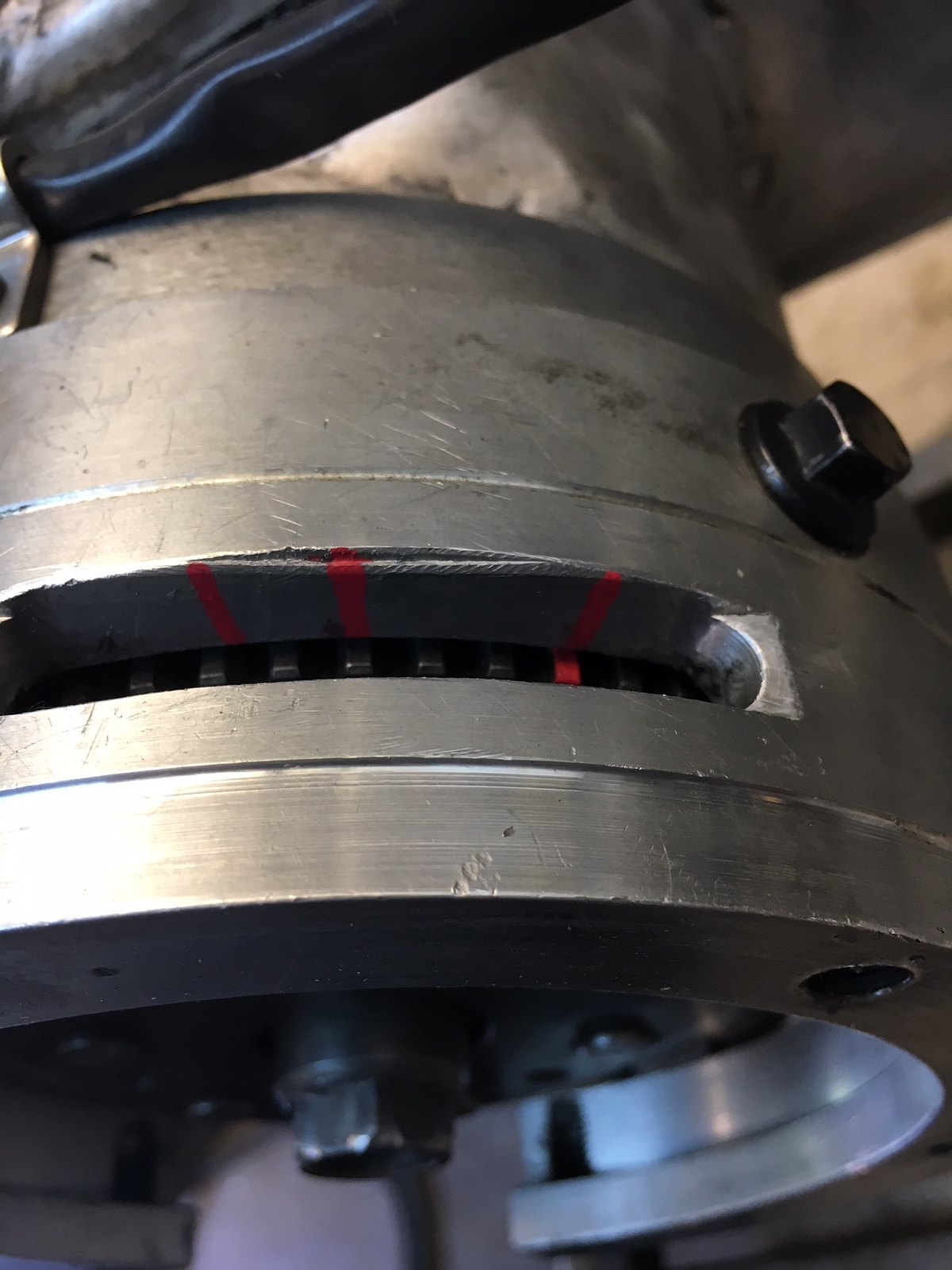

IMG_6292 by PotvinV8, on Flickr

IMG_6292 by PotvinV8, on FlickrTrued the crank as well as it was out a few thou more than I was comfortable with.

IMG_6273 by PotvinV8, on Flickr

IMG_6273 by PotvinV8, on FlickrIt's back to under a thou runout now, so all's well.

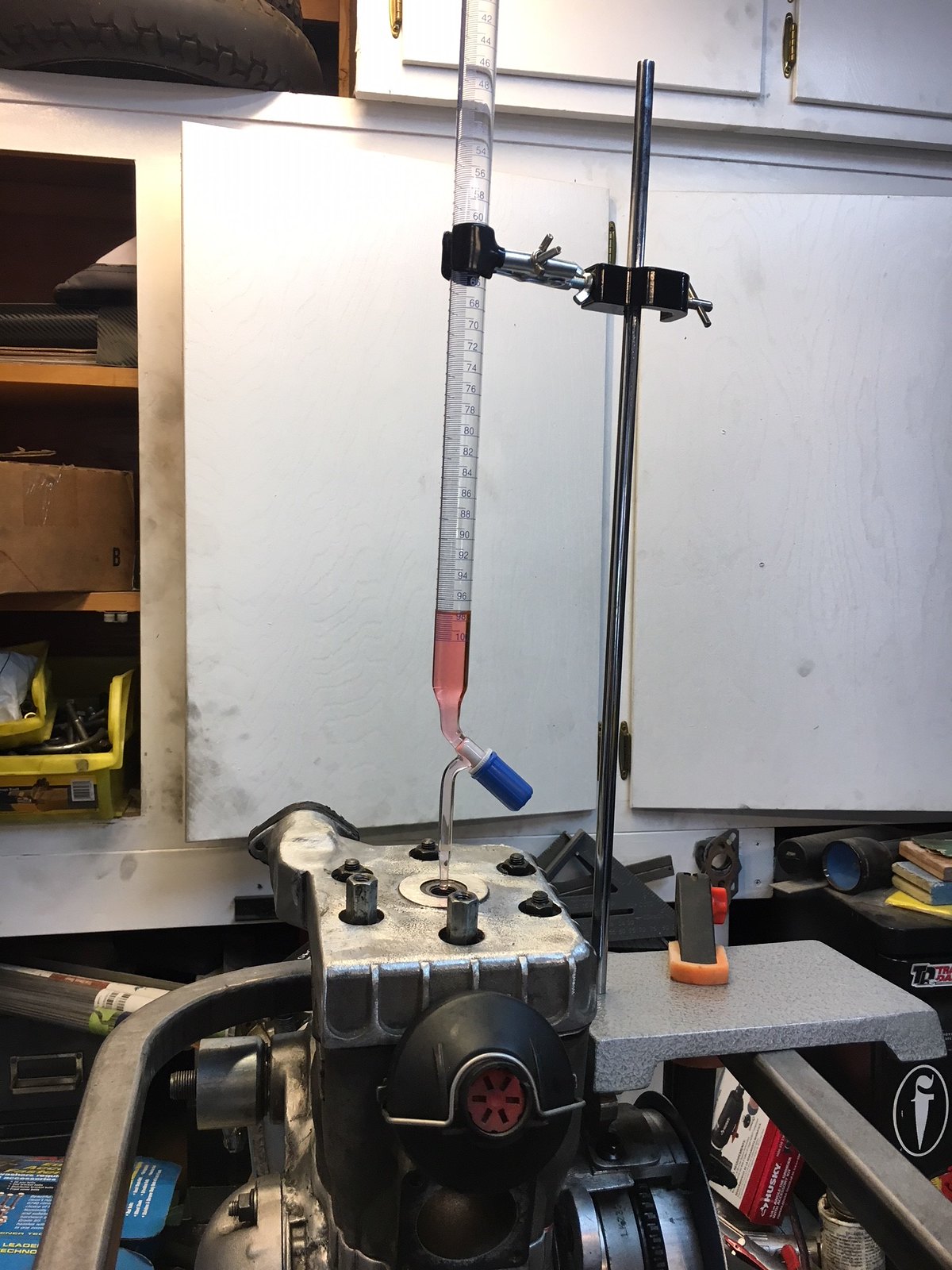

Waiting on a couple small parts then the motor should be ready for reassembly. In the meantime, I've been chasing a handful of little things and think the damage came down to too much positive deck height resulting in too much compression which built up excess heat and probably caused the piston to contact the head. Perhaps more than once! The positive deck height situation also caused the piston to hang over the exhaust port at BDC, which no doubt exacerbated the problem. I've got a new base gasket installed that puts things more in line with where they need to be and think I've got the issues whipped. Hoping to have everything back together and on the road in the next week or so. Stay tuned!