chain has a very tight play for sure... Maybe just a matter of running in.

We're lacking of a dyno in Paris. Need to go somewhere in the far north suburb to get one.

Lince 200 o-tuning à la mode fastfrog

- scooterslag

- registered user

- Posts: 411

- Joined: Wed Jan 07, 2009 12:23 pm

- Location: Sunny Barnstaple

- Contact:

-

rosscla

- registered user

- Posts: 4823

- Joined: Tue Oct 25, 2011 9:50 pm

- Main scooter: Lambretta

- Location: Lanarkshire

- Contact:

Loving it.

Still on my shopping list when I win the lottery...

Still on my shopping list when I win the lottery...

"Our dilemma is that we hate change and love it at the same time; what we really want is for things to remain the same but get better."

- fastfrog

- registered user

- Posts: 412

- Joined: Fri Dec 27, 2013 3:37 pm

- Main scooter: T5 mk1, SS180, PX200 millenium

- Location: Paris, Taxes

- Contact:

little update with a Pm disc brake conversion. The front drum was a nightmare and barely braked. Swapped it for a PM tuning volante without anti dive. I really dislike those late 70s systems that freeze handling and leaning when braking. Hazardous and unpleasant brake feeling for sure. better use harder shocks than anti dive....

Anyway the volante with its "back from the future" look fits discretely. I don't really care about the circular saw design of the disc.

Anyway the volante with its "back from the future" look fits discretely. I don't really care about the circular saw design of the disc.

Last edited by fastfrog on Tue Mar 17, 2015 11:17 pm, edited 1 time in total.

Size matters!

- fastfrog

- registered user

- Posts: 412

- Joined: Fri Dec 27, 2013 3:37 pm

- Main scooter: T5 mk1, SS180, PX200 millenium

- Location: Paris, Taxes

- Contact:

Some good news from Paris. got my papers (V5) last week. What a struggle with a spanish former owner.... more than 4 mouths to get the file completed.

I'm very close to completion by now. I'm having problems with the front tool box fitting. Leg shield was in such a bad shape that box couldn't fit properly. There was almost a 1cm gap between the 2. We had to weld extra matter to get the perfect shape. Box needs a good spray before being bolted on.

brak disc conversion:

I'm very close to completion by now. I'm having problems with the front tool box fitting. Leg shield was in such a bad shape that box couldn't fit properly. There was almost a 1cm gap between the 2. We had to weld extra matter to get the perfect shape. Box needs a good spray before being bolted on.

brak disc conversion:

Size matters!

-

Dimitrios_231

- registered user

- Posts: 202

- Joined: Mon Jan 12, 2009 4:06 pm

- Contact:

Nice thread again,

sorry,I have two questions

Did you manage to fit or use the S-Box?

Did you use the epoxy putty on the crankcase only or both on crankcase and maghouse?

I was doing an engine,small block with 200cc maghouse flange,there was a big gap,I was afraid to use epoxy putty on the maghouse.

Thanks.

sorry,I have two questions

Did you manage to fit or use the S-Box?

Did you use the epoxy putty on the crankcase only or both on crankcase and maghouse?

I was doing an engine,small block with 200cc maghouse flange,there was a big gap,I was afraid to use epoxy putty on the maghouse.

Thanks.

- fastfrog

- registered user

- Posts: 412

- Joined: Fri Dec 27, 2013 3:37 pm

- Main scooter: T5 mk1, SS180, PX200 millenium

- Location: Paris, Taxes

- Contact:

S-box still on the shelf. Next time for sure...Dimitrios_231 wrote:Nice thread again,

sorry,I have two questions

Did you manage to fit or use the S-Box?

Did you use the epoxy putty on the crankcase only or both on crankcase and maghouse?

I was doing an engine,small block with 200cc maghouse flange,there was a big gap,I was afraid to use epoxy putty on the maghouse.

Thanks.

See you are "hawkeye" dimitrios! I put the epoxy only on the crankcase side. I guess it will fly the port and finish somewhere in the exhaust.... Not today, not in a week but surely in a certain future....

We had trouble fitting the glove box. A pain! leg shield was so trashed and bumped, things couldn't fit together...

Willy had to weld extra material to shut the gap between the upper side of the box and the shield...

Things are fine now and this nice metal glove box fills this empty space behind the shield.

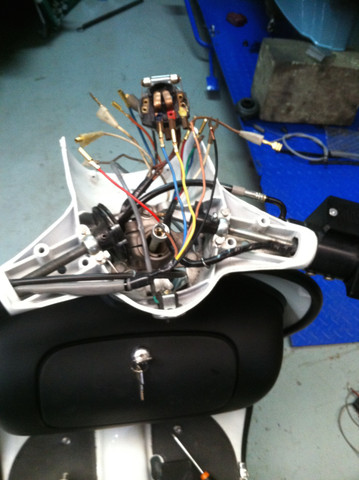

Electricity nightmare. None of the wire matchs the color code shown in the the sticky's book diagram... I'm tearing my hair off!

But things are almost completed this evening: beam, signals and horn are working fine with the battery. The DC conversion is a hit. It works fine and gives a regulated straight curent whether the engine runs or not.

Registration is completed and I got a "collection" V5.I'm not sure of the exact terms in english, but it's a cool mean to get the registration done with a foreign engine. I can also use an old french "black" license plate, much nicer than the new technocratic ugly european one....

Size matters!

looking good