I'm fitting some dampers to my forks next week, could anybody tell me the exact measurements for the height of the damper bracket?

I'll almost certainly get the brackets welded on, but are there any pros/cons of clamp-on damper brackets?

cheers fellas.

Front dampers

-

lammydave

- registered user

- Posts: 200

- Joined: Wed Jan 07, 2009 1:13 pm

- Main scooter: Li150Special RT195

- Location: Ashford, kent

- Contact:

http://www.lcgb.co.uk/workshop/fdampers.html

good quality bolt ons are fine, but for total stability and correct look, weld ons are best..

the forks must be fully stripped to get this done though

good quality bolt ons are fine, but for total stability and correct look, weld ons are best..

the forks must be fully stripped to get this done though

Li150 S2 1959. Li150 Special 1964. GP125 1970. Jet 200 Performer 1981. 1967 Sx150. 1959 Li150 S1. 1968 li125 Series 4

it depends how long the dampers are when fully extended the measurment on the lcgb is in my opinion to big bold statement i hear you say well having don 20ish top lug conversions in the last year or so i havent found any dampers that will fit there measurement a good guide is 230mm to the undereside of the bracket i would fit the damper to the botton first with the link in and wheel and hub so that the bottom is correct and fit the top log tight enought to hold it to the damper but loose so you can twist it a bit, then position the dampers so ir runs parallel up the fork leg from the side and the front, there will be a gap under the top mount most of the time or it might be to tight you need to pack the bottom pin or remove some material from the stud shoulder to get it right i,ll put some pics up later

We sleep soundly in our beds because rough men stand ready in the night to visit violence on those who would do us harm

Thanks very much for the advice lads; much appreciated.

- Monty

- registered user

- Posts: 472

- Joined: Wed Jan 07, 2009 7:21 pm

- Main scooter: Series 1 Muggy, Imola Special

- Location: STOCKPORT

- Contact:

Get your fork link studs welded on (see a very nice man called shocky) as the metal brackets sold to convert the links puts the damper in yet another place all together.

first you need to fit your links and what ever type of mounting you aer going to use for the damper if you using the indian bottom bolt type clamps then a hub needs to be fitted and then fit the damper tightly on the bottom and fit the top bracket .

the 2 arrows indicate the faces that should be parallel to each other altho you might have to make them stick out a bit to make the top mount a bit closer to the forks

second pic is the normal bottom screw in type stud were the arrow is pointing is 9mm high

this is to much on most conversions

3rd 4th and 5th pic

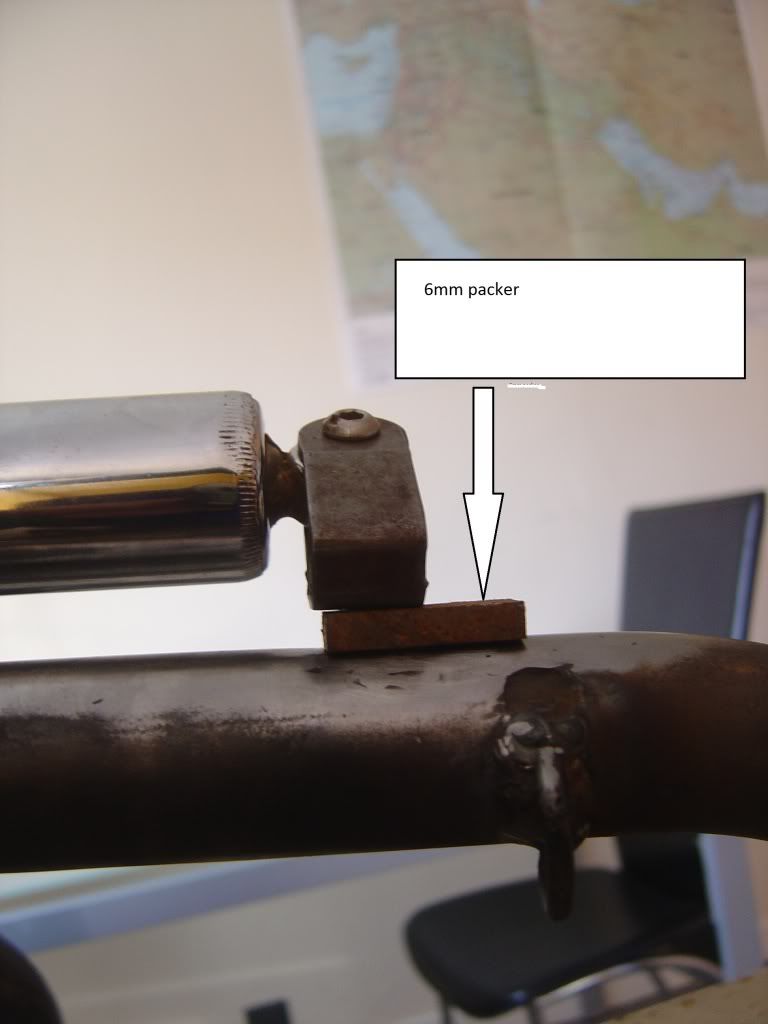

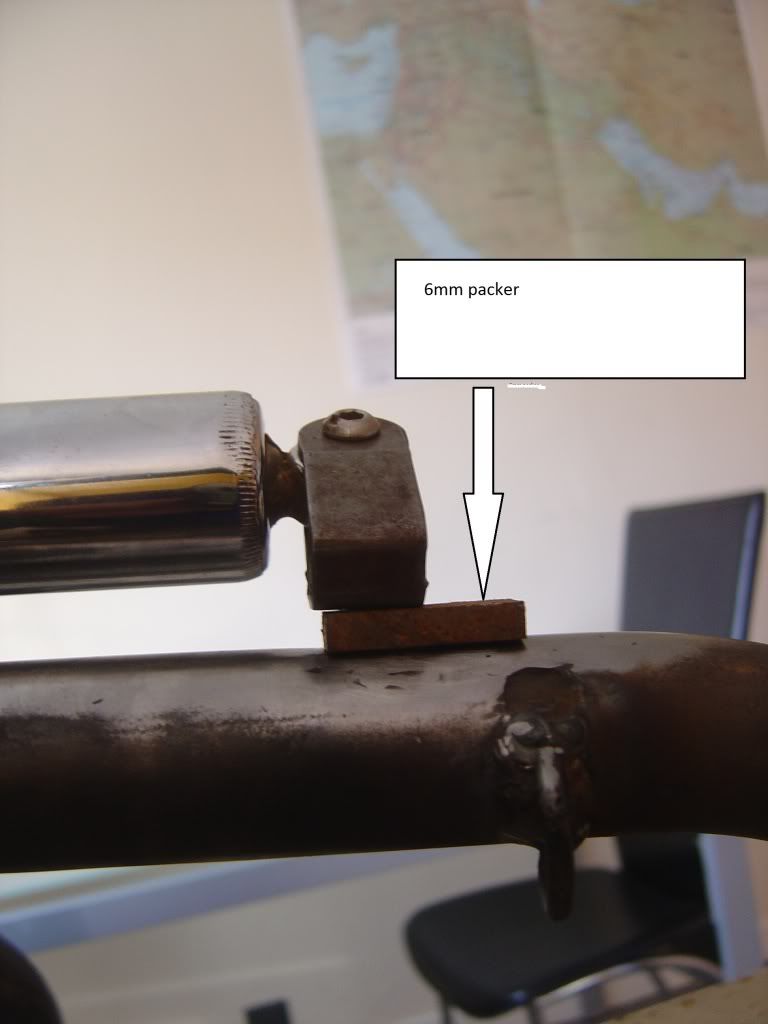

this is what the top looks like when everything is square and parellel note the 6mm packer needed to make this so (not good)

theres no way a 6mm weld would look good and it would prob bend the forks with all that heat so a solution is below

this pic shows a stud instead of the normal damper mount and some spacers this has brought the top down by 3.5mm (good)

the next pic shows the top with a 1.5 mm gap but to achieve this the top lug has been twisted slightly as well altho not enough to notice

the above set up is with screw in bottom lugs and not the bolt on indian type if you need more info or a set of links with damper mounts welded on contact me or if you want the whole lot done again contact me

the 2 arrows indicate the faces that should be parallel to each other altho you might have to make them stick out a bit to make the top mount a bit closer to the forks

second pic is the normal bottom screw in type stud were the arrow is pointing is 9mm high

this is to much on most conversions

3rd 4th and 5th pic

this is what the top looks like when everything is square and parellel note the 6mm packer needed to make this so (not good)

theres no way a 6mm weld would look good and it would prob bend the forks with all that heat so a solution is below

this pic shows a stud instead of the normal damper mount and some spacers this has brought the top down by 3.5mm (good)

the next pic shows the top with a 1.5 mm gap but to achieve this the top lug has been twisted slightly as well altho not enough to notice

the above set up is with screw in bottom lugs and not the bolt on indian type if you need more info or a set of links with damper mounts welded on contact me or if you want the whole lot done again contact me

We sleep soundly in our beds because rough men stand ready in the night to visit violence on those who would do us harm

-

dapper

- registered user

- Posts: 930

- Joined: Tue Jan 27, 2009 5:30 pm

- Main scooter: The Biriani Bullet

- Location: Brighton (well Hove actually)

- Contact:

Steve, I think you'll find that if you turn down/file off that round shoulder on the bottom damper stud in your first picture, as far as the nut shaped part, you'll be able to get the parallel look you're looking for (as discussed the other day) May save having to put that packer in.

Compact Toolbox Flywheel Holder

yes it will but that must be a right bugger to file round and it needs to round, the stud option costs £2 for studs then some washers or a packer the bought damper mounts cost about £7 for stainless ones

i would want mine machined if i had to reduce the shoulder as any flat spots or uneveness could cause a stress razor

i would want mine machined if i had to reduce the shoulder as any flat spots or uneveness could cause a stress razor

We sleep soundly in our beds because rough men stand ready in the night to visit violence on those who would do us harm