You can also get a 3mm collet for the Snap On/Bluepoint right angle grinder.

The part number is: AT1070RA19 and they are £8.40+vat.

I emailed Snap On and asked the question as most of my Burrs/Stones have a 3mm shank.

Does this tool have any kind of speed control?

Porting tools....???

Yes it does have a speed control, it has a twisty bit on the handle that varies the pressure... Thanks for the info on the 3mm collet... I will be ordering one...Stringy wrote:You can also get a 3mm collet for the Snap On/Bluepoint right angle grinder.

The part number is: AT1070RA19 and they are £8.40+vat.

I emailed Snap On and asked the question as most of my Burrs/Stones have a 3mm shank.

Does this tool have any kind of speed control?

-

Ancillotti

- registered user

- Posts: 17

- Joined: Thu Sep 03, 2009 8:35 pm

- Contact:

J1MS, how dose the NSK head compare with the blue point one? I haven't gotten round to ordering one yet as I've bought a lot of tools this month already!

I've just got a Sealey micro die grinder and it's a lot more controlable than the big (6mm) DeSeuter one I was using before, (though the 6mm one is still best for roughing out), but I did find the lack of an on/off switch is a bit disconcerting when you're connecting it to an air line (runs away with it's self on the bench), I think I'm either going to rig up a tool holder, or a solid mounted valve, for control.

I've just got a Sealey micro die grinder and it's a lot more controlable than the big (6mm) DeSeuter one I was using before, (though the 6mm one is still best for roughing out), but I did find the lack of an on/off switch is a bit disconcerting when you're connecting it to an air line (runs away with it's self on the bench), I think I'm either going to rig up a tool holder, or a solid mounted valve, for control.

The NSK's I have are cable driven off a Foredom motor through an NSK/Foredom adapter... brilliant piece of kit but not cheap, but not as expensive as a complete 3-1 NSK kit at around £1000 or more...Ancillotti wrote:J1MS, how dose the NSK head compare with the blue point one? I haven't gotten round to ordering one yet as I've bought a lot of tools this month already!

I've just got a Sealey micro die grinder and it's a lot more controlable than the big (6mm) DeSeuter one I was using before, (though the 6mm one is still best for roughing out), but I did find the lack of an on/off switch is a bit disconcerting when you're connecting it to an air line (runs away with it's self on the bench), I think I'm either going to rig up a tool holder, or a solid mounted valve, for control.

I have used the NSK's on three TS1 barrels and 2 Cast Iron barrels up to now... The access is really good, the motors reverse feature is good when using grinding points or Diamond burrs which are handy on the Nikasil in the TS barrels, the Snap On is not as user friendly I will take a photo of the NSK in the barrel compared with the Snap On... The 45 degree also adds to the access where the 90 degree struggles to reach, the 45 degree can make an otherwise awkward part more accessible.. Plus the smaller size of the NSK's compared to my old handset makes it easier to port on smaller cylinders.. The cutters & burrs are able to push right through the collet on the NSK so more or less can be left sticking out into the port, the Snap on doesn't allow this...

I even managed to tidy up an old barrel that I started over ten years ago, the transfers were far more reachable with the NSK than with any of my old tools (I hope to fit this to my GP when I get my Rapido relined)... But the Snap on is still very good, and for the price a bargain... but for me the Snap On is taking second place up to now...

-

Ancillotti

- registered user

- Posts: 17

- Joined: Thu Sep 03, 2009 8:35 pm

- Contact:

Cheers J1MS,

the comparison photo would be useful.

Previously I was using a Proxion 90 to reach the transfers and this required cutting down the shafts of burrs and grinding points, and still the access is very limited. (but a big improvement on the snapped riffler files that I used to struggle with!(I've got very small hands)).

the comparison photo would be useful.

Previously I was using a Proxion 90 to reach the transfers and this required cutting down the shafts of burrs and grinding points, and still the access is very limited. (but a big improvement on the snapped riffler files that I used to struggle with!(I've got very small hands)).

Sorry I took so long getting round to taking some photos, but this will give a comparison between the Snap on and NSK hand piecesAncillotti wrote:Cheers J1MS,

the comparison photo would be useful.

Previously I was using a Proxion 90 to reach the transfers and this required cutting down the shafts of burrs and grinding points, and still the access is very limited. (but a big improvement on the snapped riffler files that I used to struggle with!(I've got very small hands)).

The barrel in the pics was a standard SIL 200 barrel...

A view of the transfer in the bore after porting

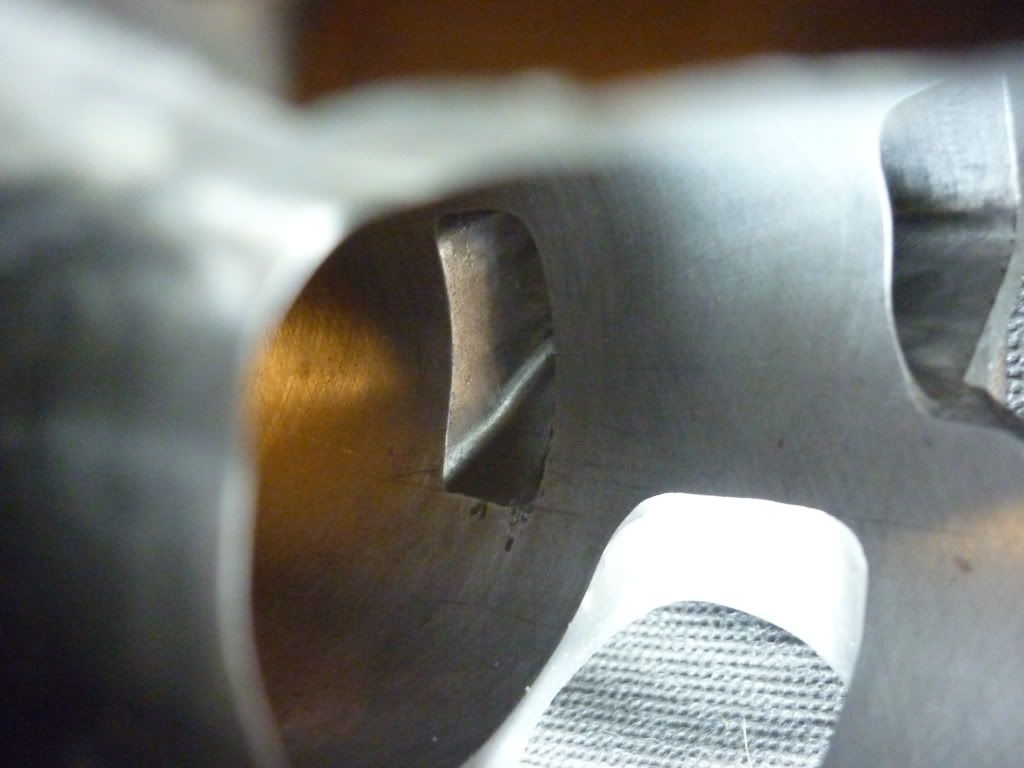

Access in the bore with the Snap on 90 degree approached through the exhaust port...

Access in the bore with the NSK 90 degree, again through the exhaust port...

From the top of the barrel showing access to the transfer side wall with the Snap on...

and the same transfer with the NSK...

This picture shows movement is a little limited by the size of the Snap on hand piece but its not impossible to get to the transfers just a little more limited...but if the barrel was a smaller bore diameter then the access would be harder with the Snap on compared with the NSK... IMO.

- rog60

- registered user

- Posts: 588

- Joined: Fri Feb 13, 2009 7:18 pm

- Main scooter: Indian GP200

- Location: SWINDON (Wilts)

- Contact:

J1MS,

As an utter novice to all this, I took your advice and bought the box of 100 asstd rubberized bits for alloy......absolutely brilliant.

I want to try some transfer port tidy-ups so would any of the e-bay type £20 - £40 die grinders be any good as a starting point and a small set of carbide grinding bits from a similar source.

I think that, to start off with, a least expensive outlay would be more sensible way to start??

Opinions greatly appreciated.........#

Great pics BTW.

As an utter novice to all this, I took your advice and bought the box of 100 asstd rubberized bits for alloy......absolutely brilliant.

I want to try some transfer port tidy-ups so would any of the e-bay type £20 - £40 die grinders be any good as a starting point and a small set of carbide grinding bits from a similar source.

I think that, to start off with, a least expensive outlay would be more sensible way to start??

Opinions greatly appreciated.........#

Great pics BTW.

NO IT'S NOT A F***IN* MOPED!!!!!!

Jumping into another persons threadrog60 wrote:

would any of the e-bay type £20 - £40 die grinders be any good as a starting point and a small set of carbide grinding bits from a similar source.

.

My original tuning in the early 80`s was done with nasty files, modified routers, emery cloth, and anything short of brick chisels.

what I have learnt since then is that the greater the selection of tools the more you can do, even very cheap grinders will save a lot of time and give you more options as to the type of work that you can carryout.

My cheapest die grinder cost £10 from aldi and has its own specific uses, buying cheap may mean that the tools don`t last more than a few barrels but will give you a chance to try your hand before commiting many hundreds of pounds. you may even end up getting a rare bargain

It`s all powerfull white mans magic

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

My Scoots,

http://i897.photobucket.com/albums/ac17 ... CF0600.jpg

http://i897.photobucket.com/albums/ac17 ... 01/035.jpg

I am no expert at porting, like most others I'm self taught. When you first try to port a barrel its more a case of finding out what doesnt work rather than what does.rog60 wrote:J1MS,

As an utter novice to all this, I took your advice and bought the box of 100 asstd rubberized bits for alloy......absolutely brilliant.

I want to try some transfer port tidy-ups so would any of the e-bay type £20 - £40 die grinders be any good as a starting point and a small set of carbide grinding bits from a similar source.

I think that, to start off with, a least expensive outlay would be more sensible way to start??

Opinions greatly appreciated.........#

Great pics BTW.

The cheap options (some are very good for porting a Lambretta barrel) are the mini drills with a flexible shaft included in the kit.

B&Q did a mini drill 135 watts with a stand, tools included and a flex shaft for about £25 (I would highly recommend it) if they are in stock.

Machine mart also sell one its about £30 which hangs from a stand, but the B&Q one if you can get one is far more user friendly http://www.machinemart.co.uk/shop/searc ... any/page/1... But there are many other makes offering similar packages.

Dremel make a couple of kits with a stand & flex shaft included but these are usually £50 plus, but are very good...(I seem to burn out Dremels unless I use them with the flex shaft) metal fillings seem to get into the motor too easily...

If you have a compressor then you can use an air powered pencil grinder, these are very small and light to use rev at speeds up to 75000 rpm and remove metal using a Tungsten burr very quickly, from around £25, I use one of these.http://cgi.ebay.co.uk/RDGTOOLS-AIR-DIE- ... 286.c0.m14

The tools needed to give a decent finish to a port are not too expensive with (pointed tree barrel and flame shapes) 3mm shaft 6mm head tungsten's, some silicone carbide burrs and varying grades and sizes of mini flap wheels.

These used with a mini drill-flex drive or a air powered pencil grinder, then all of the barrel can be accessed except the transfers in the bore (although you can make some progress in the bore but not all of the port can be accessed)

cartrige roll kits in varying grades, that fit to an arbour are available for drill speeds up to 10000 rpm with a 6mm shaft pretty easy to use and polish up exhaust & inlet ports after cutting prior to finishing with finer grade mini flap wheels.

A very good place to get the cutting tools is ebay, or next weekend the Stafford show, as they have a lot of tool stalls inside that sell cutters and stuff for porting...

If trying to get a neat finish with Tungstens, then I use cross cut or double cut Tungstens, These are less prone to juddering & remove metal a little slower when used on a slower speed can give a reasonable finish without polishing... This type of Tungsten cloggs up very easily if used on aluminium...Like these http://cgi.ebay.com/ebaymotors/Carbide- ... veQ5fTools available in 3mm shank......but these are 6mm shank but they can be used with a die grinder for fast metal removal on steel

- rog60

- registered user

- Posts: 588

- Joined: Fri Feb 13, 2009 7:18 pm

- Main scooter: Indian GP200

- Location: SWINDON (Wilts)

- Contact:

Cheers, that's given me the confidence to buy cheap to start with...............I have the Machine Mart tool with the flexible drive which broke fairly qiuckly just smoothing out inlet and exhaust ports. Apparently no spares are available............ so as I have compressor I'll get a cheap air powered tool.

NO IT'S NOT A F***IN* MOPED!!!!!!