will drilling the disc on an inboard lambretta brake help stopping ability?

if so does anyone know what size / spacing of holes works well?

what are the best pads to put in as ive heard std arent too clever?

cheers

mick

drilling inboard disc

- corrado

- Dealer

- Posts: 2588

- Joined: Thu Jan 08, 2009 1:12 am

- Main scooter: Lambretta GP

- Location: Top of Blackpool Tower

- Contact:

I wouldn't recommend it, the heat of drilling may warp the disc or potentially weaken it leading to stress fractures.

Under certain conditions where the disc gets very hot gasses are created between disc and pad that push the pads back leading to reduced braking, holes or grooves can help disipate the gasses and improve cooling under those circumstances but if the brake isn't very efficient from the off then the holes and grooves are unlikely to improve things. Sintered pads may help but the Lambretta disc is a pretty flawed design and probably only converting it to hydraulic is going to give you a decent brake.

Under certain conditions where the disc gets very hot gasses are created between disc and pad that push the pads back leading to reduced braking, holes or grooves can help disipate the gasses and improve cooling under those circumstances but if the brake isn't very efficient from the off then the holes and grooves are unlikely to improve things. Sintered pads may help but the Lambretta disc is a pretty flawed design and probably only converting it to hydraulic is going to give you a decent brake.

i have done it but they are avalible new in a vented/drilled style

Its in bits scooter club: www.facebook.com/groups/132415046859320

rally season has started so limited funds - can get it drilled at work so didnt want to buy one

cheers

mick

cheers

mick

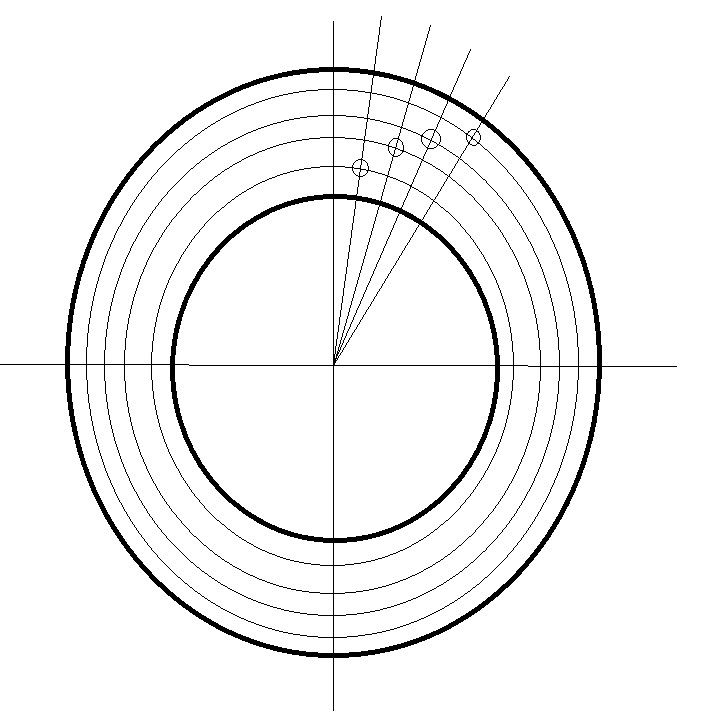

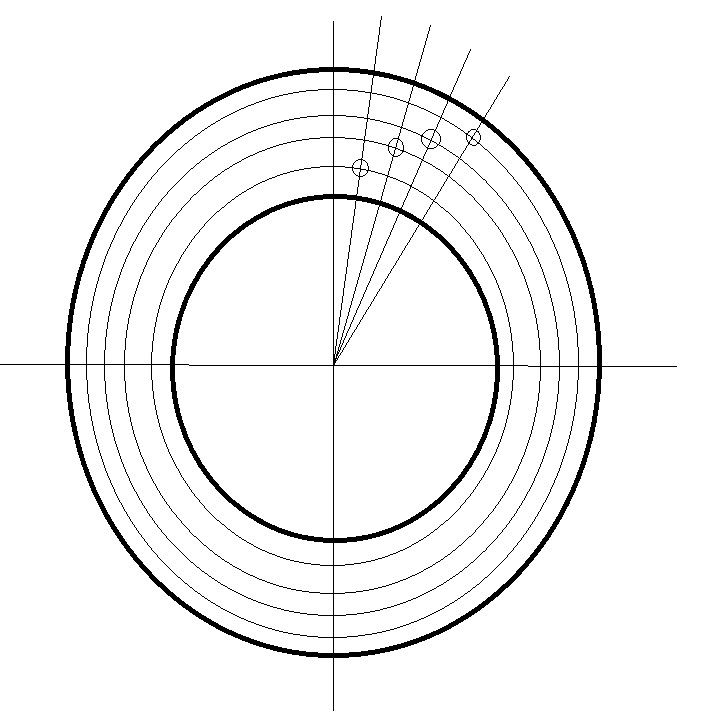

ok ....what i did was this .....get a peice of mdf (about 6mm thick)

get your self a compass ,ruler and a protractor ,

measure the disc diameter and the depth of the disc face ,and draw on the board ,so a circle within a circle

then divide the distance between them so you have 4 more circles within the first two

still with me?

now get your protractor and divide into 10degree segments

then mark where the line intersects on the bottom line -

after making four holes go back to the bottom line and repeat

this should work out so the last hole you mark will be a top one ("should" as i did this 20yrs back)

screw some wood to the mdf to keep your disc in position and drill through the mdf into the disc with a small drill then remove pattern and you can then use progressively larger drills till you are happy with the size

but given corrados advice i leave it up to you ...ok

get your self a compass ,ruler and a protractor ,

measure the disc diameter and the depth of the disc face ,and draw on the board ,so a circle within a circle

then divide the distance between them so you have 4 more circles within the first two

still with me?

now get your protractor and divide into 10degree segments

then mark where the line intersects on the bottom line -

after making four holes go back to the bottom line and repeat

this should work out so the last hole you mark will be a top one ("should" as i did this 20yrs back)

screw some wood to the mdf to keep your disc in position and drill through the mdf into the disc with a small drill then remove pattern and you can then use progressively larger drills till you are happy with the size

but given corrados advice i leave it up to you ...ok

Its in bits scooter club: www.facebook.com/groups/132415046859320

top man ricspeed - just what i was after

thanks

mick

thanks

mick

...only time it's worth drilling is when you get brake fade from overheating...but that would only really happen in extreme circumstances....on a road scoot i think its good to get a bit of heat into the brakes...use the copper coloured pads all other pads are s**t other than citreon bx rear pads but these are dangerous when worn down!

thanks joey

are the copper coloured ones the "sintered" ones?

are the copper coloured ones the "sintered" ones?

...there on ve uk race sintered...

ohjoey wrote:...there on ve uk race sintered...