Hi Dan,

At long last I am grabbing a few minutes to give you a bit more info:

As you probably know I do not have a Dynamometer so all figures given out before have been by independent means.

Neither has there been a special kit produced to achieve the figures already given out, in fact it is the reverse. The production sample cylinder that was used at Diablo Motors had a welded up piston as the correct Mitaka pistons had not arrived, as with any alloy welding there is some distortion especially on a piston. See attach photo, so in theory the production kit should as good or better. See picture of the exact piston used at Diablo, welded and prepared by hand, it did not seize and has not since:

The inception of the kit began back in November of 2009, having studied the market it seemed ridiculous to produce another high end kit based on high rpm. As I am a lover of revvy kits it was going against the grain.

So what next? It had to be different and as I had spent most of that year trying to find out why the majority of the oil in my GP was being dumped in the crankcase coupled with the fact that unleaded fuel burns so hot with half the country blowing up engines a few idea’s started to come to mind utilizing one of the three brains cells I had left after a brain haemorrhage I had in October 2007.

Over the Christmas period I worked on two Innocenti cast iron cylinders to prove the theory of the port timings. In January 2010 my GP was being run in around London by Dave H who commuted to work every day. I cannot say a welded bridge in an iron barrel using unleaded fuel is safe by any stretch of imagination. But it worked well so it was on to the next stage, whilst the cylinder was running around London I was measuring how much space we had to play with or lack of it.

By the end of February I had drawn the whole cylinder and head, each individual fin as they are all different in some way on a drawing board at home. My first job when I left school was in a drawing office as a trainee design engineer so I do have some idea on drawings. Then off to see Adam Winstone who does cad work (only 2D though) a couple of meetings with him and the first production drawings were ready in March, various alterations later and it was ready.

In May I got my first quote to produce the patterns and castings for the cylinders and heads, learnt about the process which meant I had to remove 2 fins from my original drawing! Back to Adam and revamp the whole thing. Now I knew how much it was going to cost put a bit of a damper on things as I had to keep the retail price within a certain range. Producing a kit in the UK was to be expensive but to get them done else where would have meant ordering at least 500 units! So I kept the price down by ordering 1,000 pistons, yep that is not a miss print 1,000 !!!

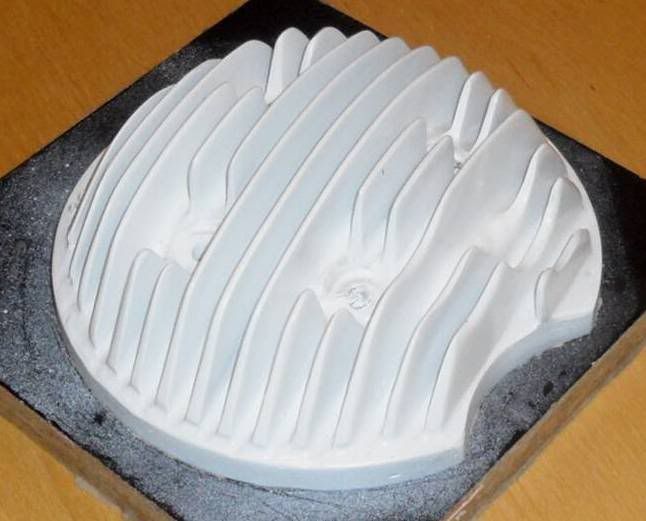

By December 2010 I had found another pattern maker (I had seen six) found some money and off we went, the point of no return. To save a bit of money, peanuts in the whole scheme of things I made the cylinder head pattern myself, bought a wood lath. Things are never as simple as you first imagine! First attempt took me a week, binned that, second one also took a week but this time I knew what I was doing.

This is it all made out of wood………. Photo of pattern:

By 4th January 2011 the pattern maker makes a start, say’s it will take two weeks, seven weeks later it is finished! You have to see it ones self to see just how much work goes in to making a two stroke cylinder pattern. If anyone knows how sand casting works, you have core boxes which are the sand castings, there were seven in this when we started there are eight now. Each box has a mixture of sand and resin packed into it to produce a moulding of every shape in the cylinder. These all have locating pins to slot together, easy peesy, NOT! This pattern maker is a master craftsman and I mean MASTER.

So this is the first cylinder out of the foundry in its raw state, Photo’s taken at the foundry:

When I saw this my heart sank, all sort of words came to mind! Now the foundry managers nickname is 'Jumbo' and as with all nicknames there is some truth in them, get the picture? So fearing for my life and as I did not know him too well at that time I thought it inappropriate to say "what is that f**king load of sh*t!!!" However he then explained the next process that it would be de-burred and sand blasted, in my mind it was not possible but he was right! â€Oh ye of little faith†;o)))

So the pre-production MK 1 kits were done, pistons came in and OH sh*t they were wrong, the indent around the gudgeon pin kept the exhaust port open! So ordered MK2 pistons, and whilst waiting for those I kept wondering how I could add extra transfer area as it was not possible to put in the conventional duel transfers because of the extra wide exhaust port, it was just not possible. So was born the wrap over port, bloody tight to get in above the inlet port but it was done. Now I had to decide should I wait and do an update in a year or so, commercially it should be left, morally it should be done from the outset, so there you have it.

Once the casting are produced by the foundry and cleaned they then go off to be heat treated, not sure if any of the other kits on the market do this but this one is. It helps stabilization. They are then transported to the machine shop to be CNC machined, and then back to me. I have to check the cylinders chamfer all the ports and match them to the gaskets, YES....I DO THIS AND YOU DO NOT PAY EXTRA! They then go of to be Nickel Silicone Carbide coated & back to me. Each cylinder has the ring gap checked and logged, piston clearance is checked and studs are put in. All the content is checked off & packed.

Apart from all of the above also got the base gaskets manufacture in the UK too and that includes the material. These will also be on general sale soon as they have extra material around the transfer ports.

All of the kit instructions must be adhered to, if you keep to them there should not be any problems. Should there be any issues I will always rectify them, on the other hand if someone tries to con me by lying and trying to pull the wool over my eyes I will always know and believe me I will. Be straight and I will be the same.........

What’s to come?

For you tuners out there you can order kits without being plated, not too cheap doing it this way but at least you do not have to re-plate the cylinder! These will be supplied as they come from the machine shop no chamfering or matching.

We will also be offering longer cylinders, again to order only, we can give up to plus 3-4mm to the base and plus 5mm to the top face,

the exact measurements will be given in the New Year.

The inlet port as you will know has two different plane angles, from a standard cylinder one of these angles has been changed to allow an extra 6mm thickness to the top edge of the port to allow for finger ports to be machined into the cylinder if so wished.

The three outside walls of the transfer walls are 8mm thick should you want to play with them.

The wrap over port should not be touch except at the entrance to the bore.

One friendly word of advice to any rookie tuner, when you see the bridged exhaust port and think how much wider you can make it, think first or ask a grown up, or better still make sure the grown knows what they are doing otherwise it will be a trip to the alloy welder or in the bin or both! There are pit falls that you may not think about initially. And please do not make the bridge thinner, well you can, and then I can sell you another cylinder!

Heads

We can supply blank heads too, again to order only as they have to be pulled from production. Price on request.

At this moment in time we cannot conduct any one off’s as all the CNC machines have been pre-programmed. Any request will have to be priced accordingly and time frame.

The Small Block

This is all ready to go and should produce around 20 b.h.p out the box unfortunately this will NOT be in production until we have sold between 300-400 TT3 kits depending on how many are sold through trade outlets.

My Thanks to:

Adam Winstone : Cad Drawings

Peter Brunskill : Head cowl pattern

Ben Moss: Web site animation

Jack Moss: Web site design

Wow....one hell of a write up from Ron, very pleased with that, and the information is outstanding....a great insight into what goes on behind the scenes of a dedicated Lambretta enthusiast.

Thanks

Dan

And anyone wanting to contact Ron for more information or to place an order, please see his website: http://www.supertune.co/index.php?route ... duct_id=51 or phone: 07951952768