Page 8 of 20

Re: lambretta 290 rotax

Posted: Fri May 05, 2017 11:00 pm

by holty

hi daz, simple way to think of is a one way valve, its self governing, in other words when the engine crankcase creates a vacumn the valve opens allowing fuel and air mixture in, when a positive crankcase pressure is created the valve closes so ingested mixture cannot escape,its then sent to the transfer ports and then combusted above the piston, allows inlet timing to be much longer duration than that of a normal piston port engine, a more modern inlet system introduced in motorcycles mainly during the 1970s/80s and is standard fitment on most modern 2 strokes these days, helps to reduce fuel spitback out of the carb as well.

Re: lambretta 290 rotax

Posted: Sat May 06, 2017 7:35 am

by dazblakey

Cheers Holty

Read all this thread tonight really interesting great explanations keep it up mate and the others guys

Sent from my D6603 using Tapatalk

Re: lambretta 290 rotax

Posted: Sat May 13, 2017 9:47 pm

by holty

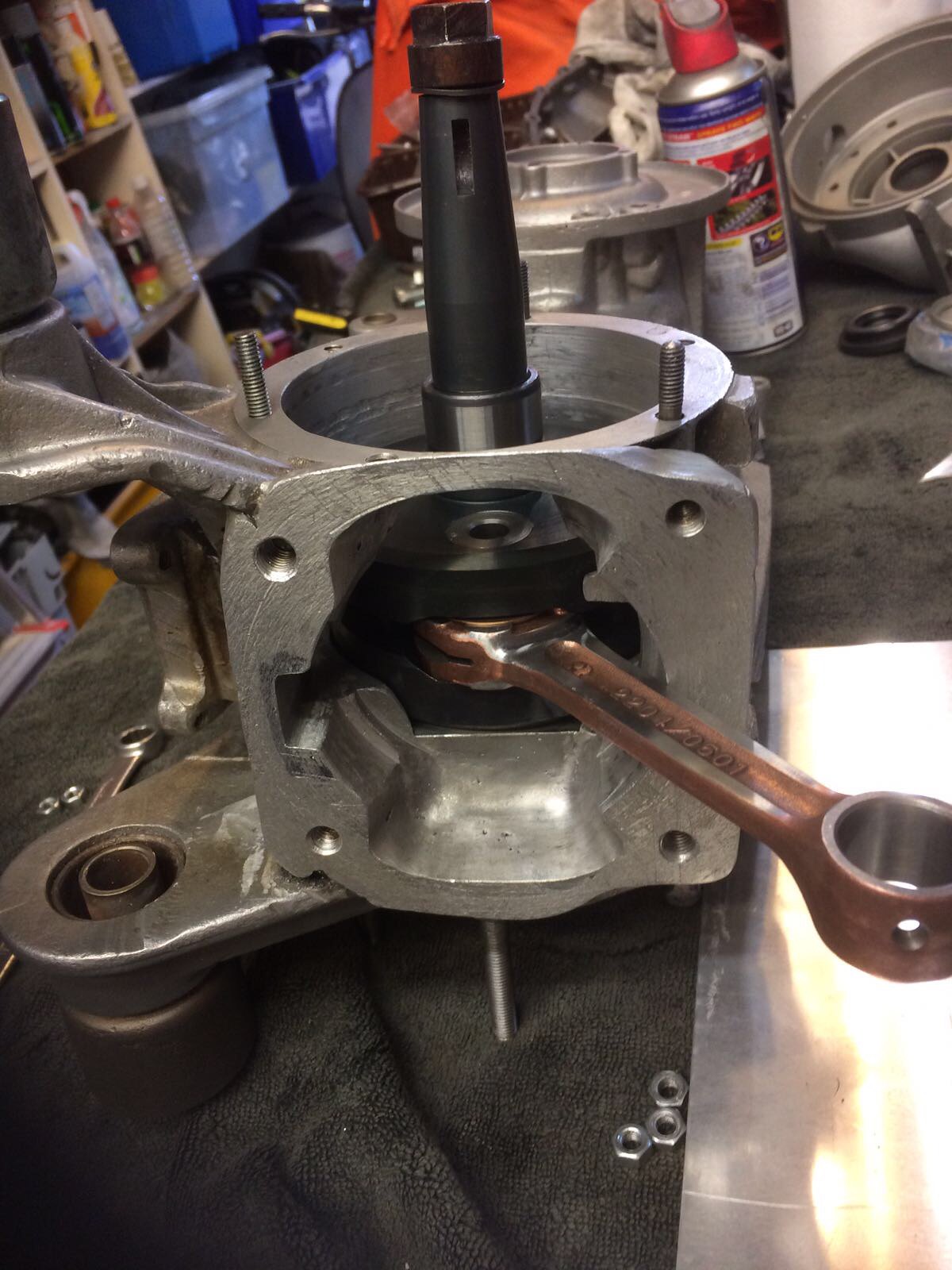

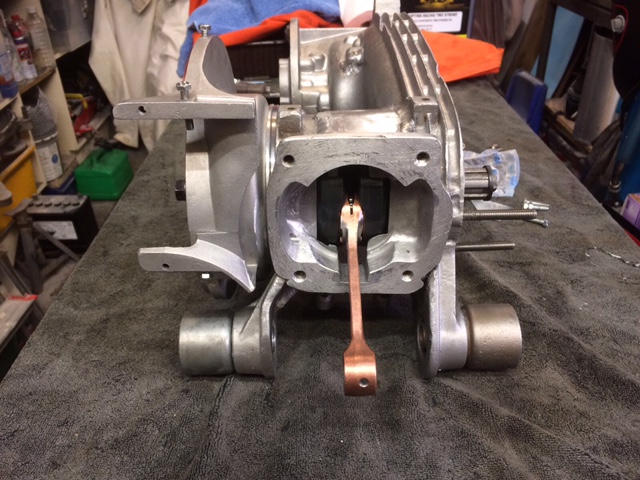

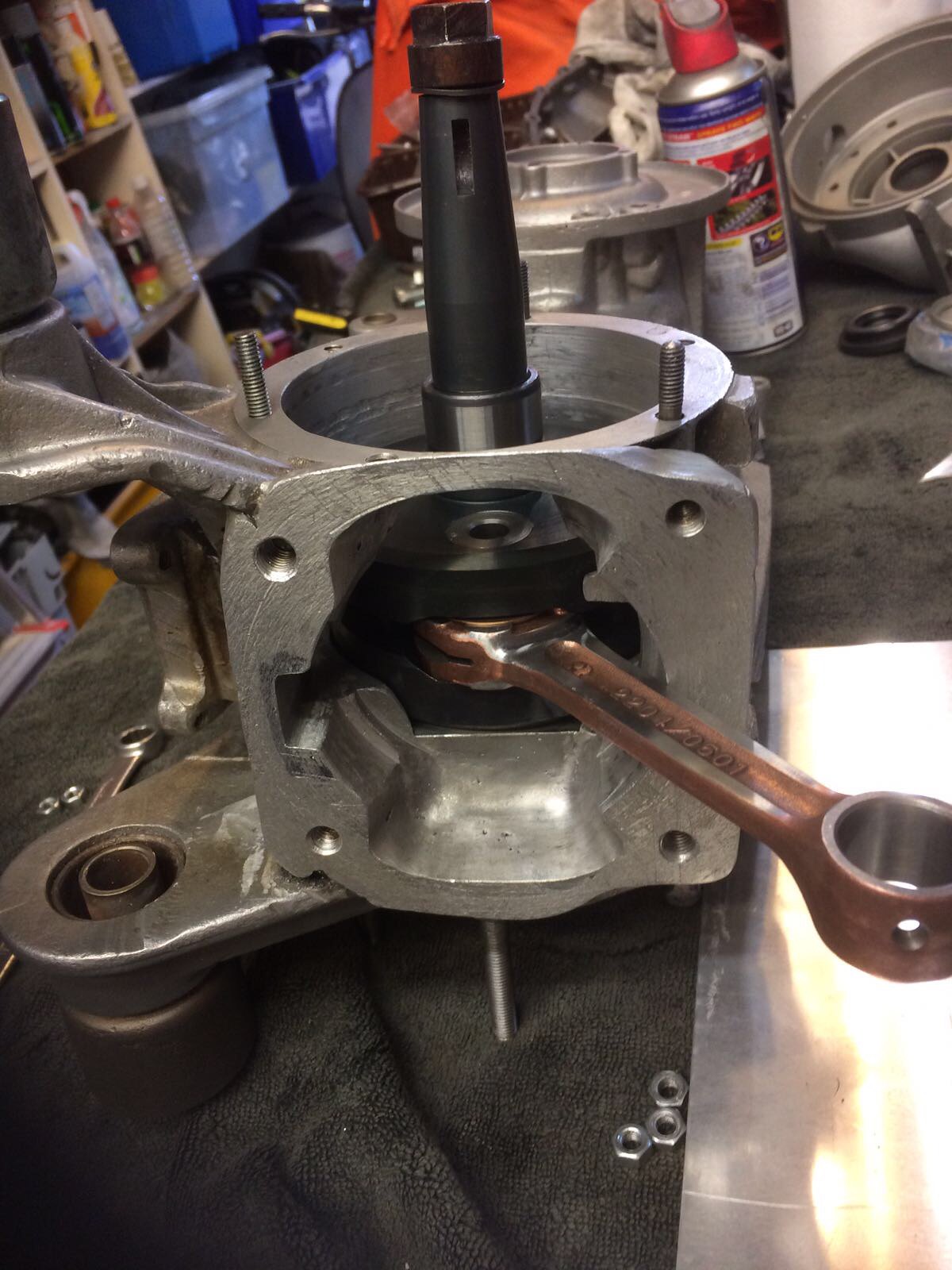

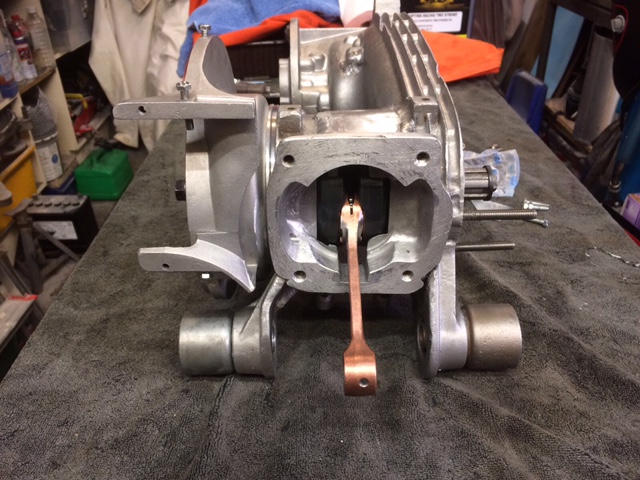

ive done an all day session in the garage working on my case, heres a few pics, first is the crankcase opened up big engough for the crank webs, next shows the circlip to retain the drive side main bearing, and you can see the trench ive cut to give the big end some clearance, and then a view looking into the inlet, some more shaping here and there, but happy with the progress.

[img

IMG_0631_zpsyom10gfk

IMG_0631_zpsyom10gfk by

stephen holt, on Flickr][/img]

[img

IMG_0645_zpswwuejkwu

IMG_0645_zpswwuejkwu by

stephen holt, on Flickr][/img]

[img

IMG_0646_zpsopw0kskq

IMG_0646_zpsopw0kskq by

stephen holt, on Flickr][/img]

Re: lambretta 290 rotax

Posted: Fri Jul 21, 2017 9:36 pm

by holty

[img

IMG_0941

IMG_0941 by

stephen holt, on Flickr][/img]

a pic showing the drive side oilseal fitted

Re: lambretta 290 rotax

Posted: Fri Jul 21, 2017 9:44 pm

by holty

before the oilseal was fitted, bearing fitted and circlip

[img

IMG_0932

IMG_0932 by

stephen holt, on Flickr][/img]

Re: lambretta 290 rotax

Posted: Fri Jul 21, 2017 9:58 pm

by holty

[img

IMG_0942

IMG_0942 by

stephen holt, on Flickr][/img]

first fitting of the crankshaft

[img

IMG_0943

IMG_0943 by

stephen holt, on Flickr][/img]

and then magflange and packers in place

Re: lambretta 290 rotax

Posted: Fri Jul 21, 2017 10:02 pm

by holty

[img

IMG_0944

IMG_0944 by

stephen holt, on Flickr][/img]

piston fitted to rod, just to check clearance at bdc, i neednt have worried there was plenty of clearance.

Re: lambretta 290 rotax

Posted: Sat Jul 29, 2017 6:46 pm

by holty

Re: lambretta 290 rotax

Posted: Sat Jul 29, 2017 6:48 pm

by holty

i had o do some repairs to the endplate studs, so i added 2 extra ones while i was at it in an effort to make it stronger

IMG_0933

IMG_0933 by

stephen holt, on Flickr

Re: lambretta 290 rotax

Posted: Sat Jul 29, 2017 6:54 pm

by garry inglis

hi holty that circlip on the bearing looks great and that reed valve opening looks massive what reed are you useing